Chidule cha Ntchito

Zojambula Zogwirira Ntchito: Kutengera zojambula za CAD zoperekedwa ndi Party A Zofunikira Zaukadaulo: Kukweza kuchuluka kwa malo osungiramo silo ≥kuchuluka kwa ola limodzi

| Mtundu wa Workpiece | Kufotokozera | Machining nthawi | Kuchuluka kwa yosungirako/ola | Chiwerengero cha mawaya | Chofunikira |

| SL-344 atolankhani mbale | 1T/2T/3T | 15 | 240 | 1 | Zogwirizana |

| 5T/8T | 20 | 180 | 1 | Zogwirizana | |

| SL-74 Dongosolo La mphete Pawiri | 7/8-8 | 24 | 150 | 2 | / |

| 10-8 | 25 | 144 | 2 | / | |

| 13-8 | 40 | 90 | 2 | / | |

| 16-8 | 66 | 55 | 1 | / | |

| 20-8 | 86 | 42 | 2 | / |

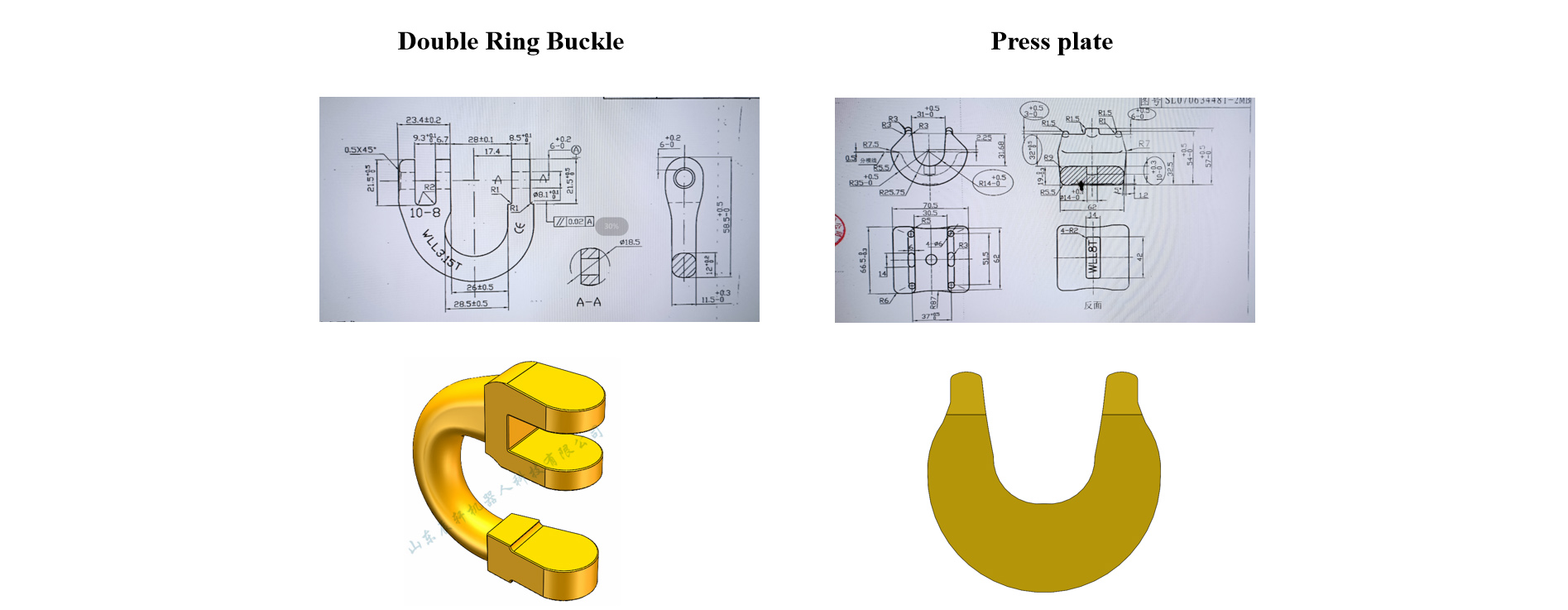

Zojambula za workpiece, chitsanzo cha 3D

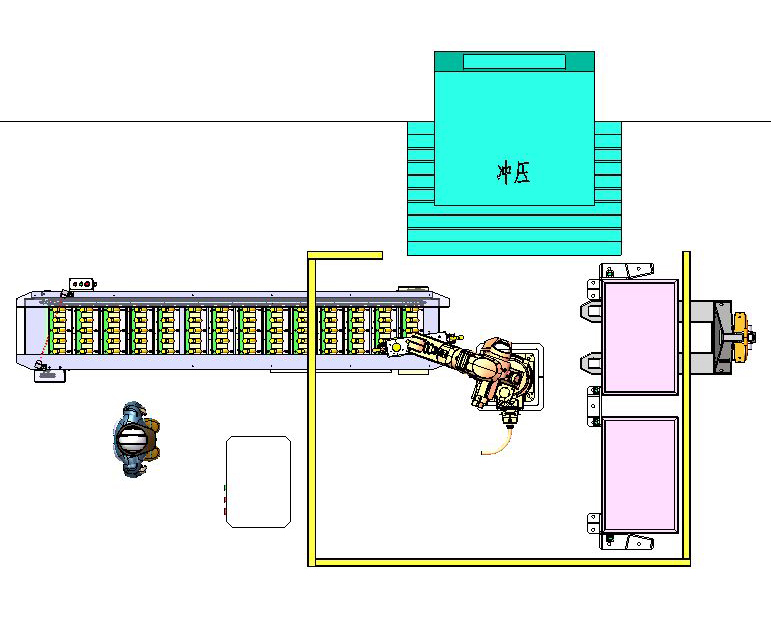

Mapangidwe a Chiwembu

Kufotokozera: Dera latsatanetsatane la malo okhala liyenera kutengera kapangidwe kake.

Mndandanda wa Zida

Dengu la kusungirako kwakanthawi kwa mbale zogawa

| S/N | Dzina | Chitsanzo No. | Kuchuluka. | Ndemanga |

| 1 | Maloboti | XB25 | 1 | Chenxuan (kuphatikiza thupi, kabati yowongolera ndi chiwonetsero) |

| 2 | Mtundu wa robot | Kusintha mwamakonda | 1 | Chenxuan |

| 3 | Malo a robot | Kusintha mwamakonda | 1 | Chenxuan |

| 4 | Electrical Control System | Kusintha mwamakonda | 1 | Chenxuan |

| 5 | Kutsegula chotengera | Kusintha mwamakonda | 1 | Chenxuan |

| 6 | Chitetezo mpanda | Kusintha mwamakonda | 1 | Chenxuan |

| 7 | Chida chodziwira choyikapo chimango | Kusintha mwamakonda | 2 | Chenxuan |

| 8 | Chimango chopanda kanthu | / | 2 | Yokonzedwa ndi Party A |

Kufotokozera: Table ikuwonetsa mndandanda wamasinthidwe a malo ogwirira ntchito.

Kufotokozera zaukadaulo

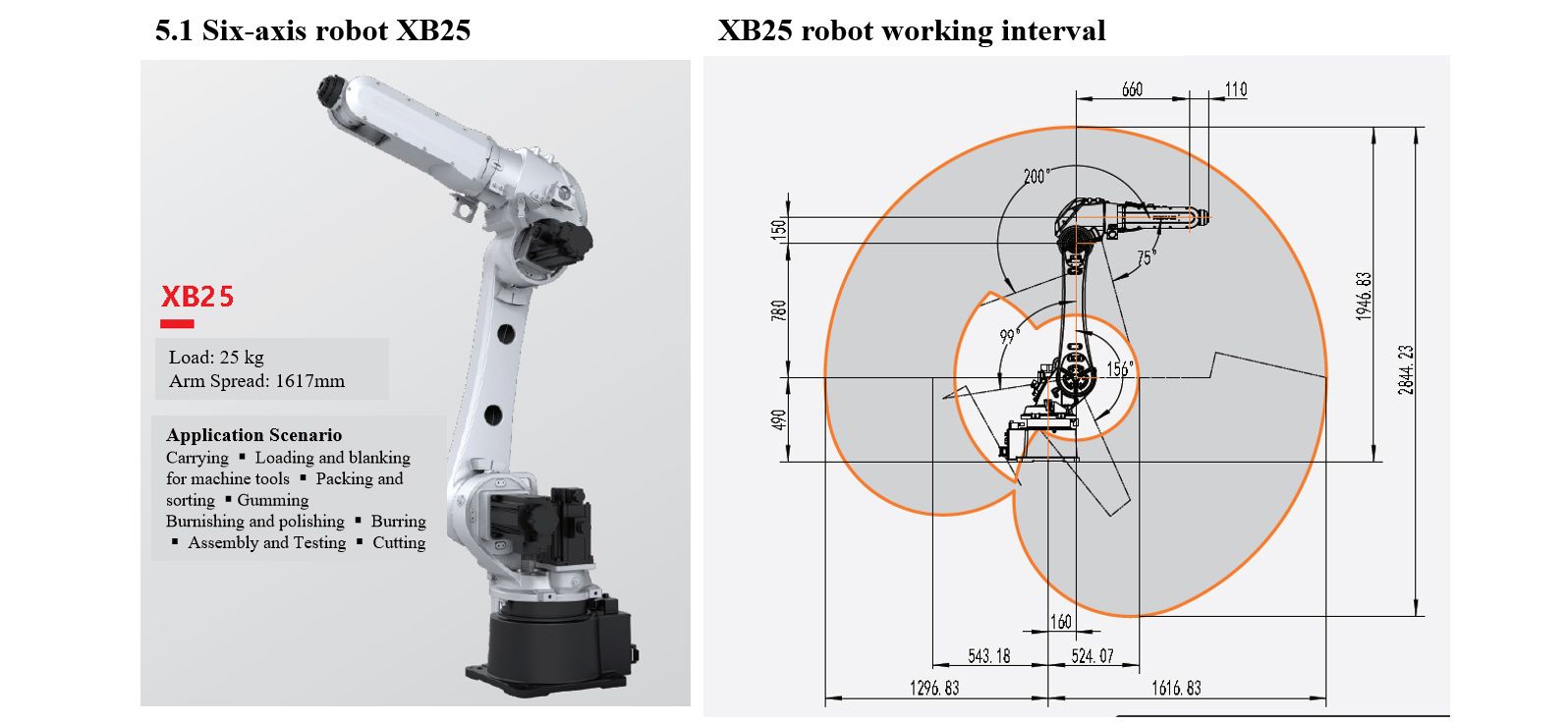

Roboti ya 6-axis XB25

Robota XB25 als grundlegende chizindikiro

| Chitsanzo No. | Digiri ya Ufulu | Wrist Katundu | Maximum ntchito radius | ||||||||

| XB25 | 6 | 25kg pa | 1617 mm | ||||||||

| Kubwerezabwereza kulondola kwa malo | Kulemera kwa thupi | Gawo la chitetezo | Kuyika mode | ||||||||

| ± 0.05mm | Pafupifupi. 252kg pa | IP65(Wrist IP67) | Pansi, kuyimitsidwa | ||||||||

| Gwero la mpweya wophatikizidwa | Gwero la Signal Integrated | Adavotera mphamvu ya thiransifoma | Chowongolera chofananira | ||||||||

| 2-φ8 mpweya chitoliro (8 bar, valavu ya solenoid yomwe mungasankhe) | 24-channel chizindikiro (30V, 0.5A) | 9.5 kVA | Chithunzi cha XBC3E | ||||||||

| Kusiyanasiyana koyenda | Kuthamanga kwakukulu | ||||||||||

| Shaft 1 | Shaft 2 | Shaft 3 | Shaft 4 | Shaft 5 | Shaft 6 | Shaft 1 | Shaft 2 | Shaft 3 | Shaft 4 | Shaft 5 | Shaft 6 |

| + 180°/-180° | + 156°/-99° | + 75°/-200° | + 180°/-180° | + 135°/-135° | +360°/-360° | 204°/S | 186°/S | 183°/S | 492°/S | 450°/S | 705°/S |

Mtundu wa robot

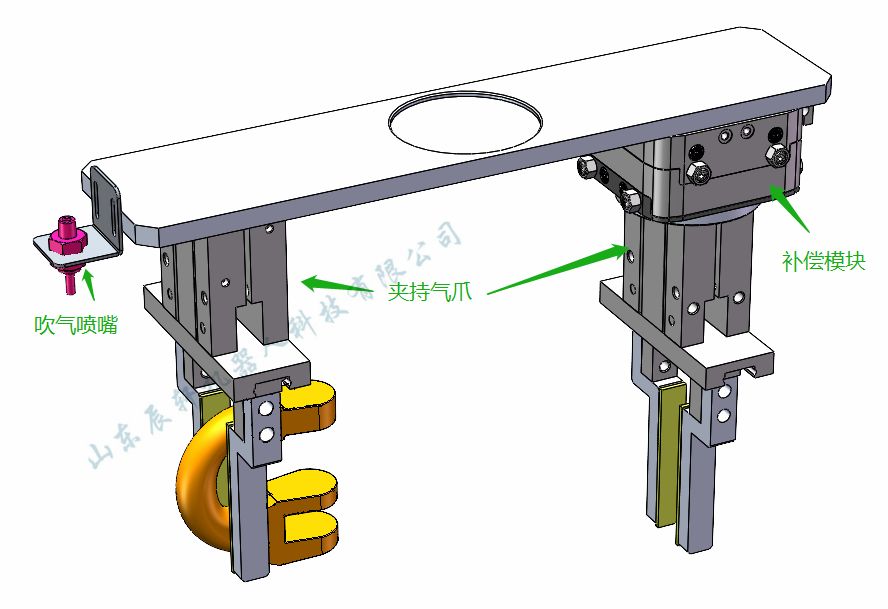

1. Kapangidwe ka masiteshoni awiri, kutsitsa kophatikizika ndi kutseka, kutha kuzindikira ntchito yotsegulanso mwachangu;

2. Ingogwira ntchito ku clamp workpieces ya specifications, ndi tong ndi n'zogwirizana ndi clamping wa workpieces ofanana mkati osiyanasiyana osiyanasiyana;

3. Kugwiritsira ntchito mphamvu kumatsimikizira kuti mankhwalawa sangagwe mu nthawi yochepa, yomwe ili yotetezeka komanso yodalirika;

4. Gulu la ma nozzles othamanga kwambiri amatha kukumana ndi ntchito yowomba mpweya pamalo opangira makina;

5. Zida zofewa za polyurethane zidzagwiritsidwa ntchito pomanga zala kuti mupewe kukanikiza kwa workpiece;

6. The gawo malipiro akhoza basi kubwezera workpiece udindo kapena zolakwika za fixture ndi kusiyanasiyana kwa workpiece kulolerana.

7. Chithunzicho ndi chongofotokozera zokhazokha, ndipo tsatanetsataneyo idzagwirizana ndi mapangidwe enieni.

| Technical Data* | |

| Order No. | XYR1063 |

| Kulumikiza ma flanges molingana ndi EN ISO 9409-1 | TK 63 |

| Katundu Wovomerezeka [kg]** | 7 |

| Ulendo wa X/Y wozungulira +/- (mm) | 3 |

| Center Retention Force (N] | 300 |

| Non-center Retention Force [N] | 100 |

| Kuthamanga kwambiri kwa mpweya [bar] | 8 |

| Kutentha kochepa kwambiri kwa ntchito [°C] | 5 |

| Kutentha kopitilira muyeso [°C] | + 80 |

| Kuchuluka kwa mpweya wodyedwa paulendo uliwonse [cm3] | 6.5 |

| Mphindi ya inertia [kg/cm2] | 38.8 |

| Kulemera [kg] | 2 |

| *Zida zonse zimayesedwa pa 6 bar air pressure **Ikasonkhanitsidwa pakati |

Malipiro gawo

The gawo malipiro akhoza basi kubwezera workpiece udindo kapena zolakwika za fixture ndi kusiyanasiyana kwa workpiece kulolerana.

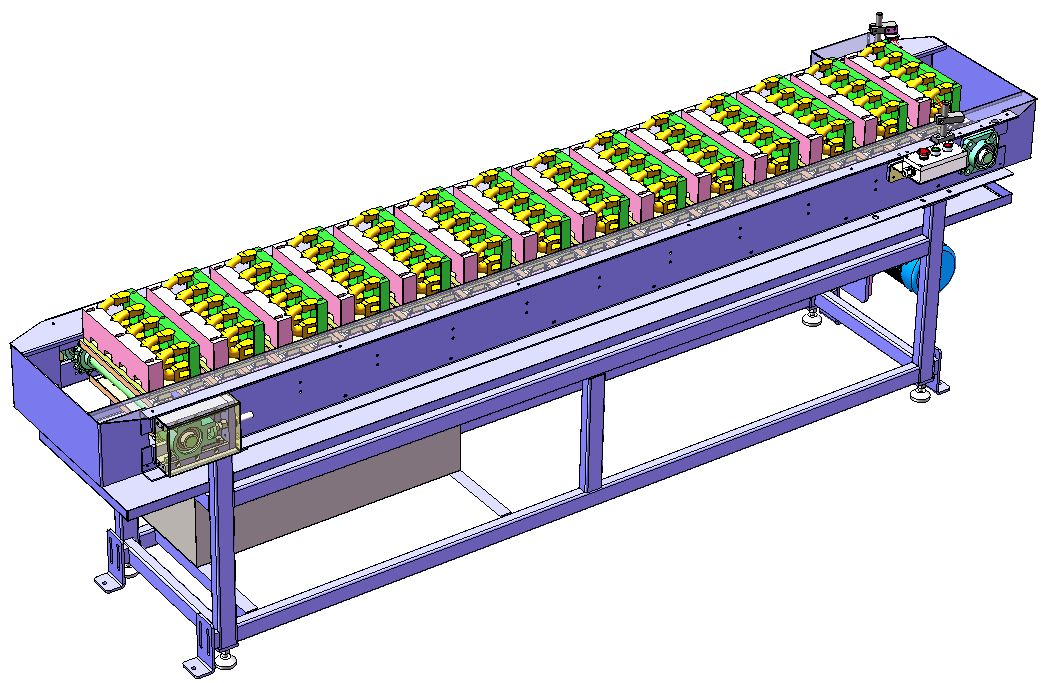

Mzere wotsegula ndi wotumizira

1. Kuyika ndi kutumizira mzere kumatengera mawonekedwe a unyolo wosanjikiza umodzi, wokhala ndi mphamvu yayikulu yosungira, yosavuta kugwiritsa ntchito pamanja komanso magwiridwe antchito okwera mtengo;

2. Kuchuluka kopangidwa kwazinthu zomwe zayikidwa kudzakumana ndi mphamvu yopanga ola limodzi. Pansi pa kudyetsa pafupipafupi pamanja mphindi 60 zilizonse, kugwira ntchito popanda kutseka kumatha kuchitika;

3. Thireyi yazinthu imakhala yosalakwitsa, kuti ithandizire kutulutsa kosavuta kwamanja, ndi zida za silo zopangira zida zamitundu yosiyanasiyana ziyenera kusinthidwa pamanja;

4. Mafuta ndi madzi osagwira ntchito, otsutsa-kukangana ndi amphamvu kwambiri amasankhidwa kuti azidyetsa thireyi ya silo, ndipo kusintha kwamanja kumafunika popanga zinthu zosiyanasiyana;

5. Chithunzicho ndi chongofotokozera zokhazokha, ndipo tsatanetsataneyo idzagwirizana ndi mapangidwe enieni.

Electrical Control System

1. Kuphatikizira kuwongolera dongosolo ndi kulumikizana kwa ma sign pakati pa zida, kuphatikiza masensa, zingwe, trunking, masiwichi, ndi zina zambiri;

2. Chigawo chodziwikiratu chimapangidwa ndi nyali ya alamu yamitundu itatu. Panthawi yogwira ntchito bwino, nyali yamitundu itatu imawonetsa zobiriwira; ndipo ngati unityo ikulephera, nyali yamitundu itatu idzawonetsa alamu yofiira pakapita nthawi;

3. Pali mabatani oima mwadzidzidzi pa kabati yolamulira ndi bokosi lowonetsera la robot. Pakakhala ngozi, batani loyimitsa mwadzidzidzi limatha kukanidwa kuti muzindikire kuyimitsidwa kwadzidzidzi ndikutumiza chizindikiro cha alarm nthawi yomweyo;

4. Kupyolera mu chiwonetsero, tikhoza kupanga mitundu yambiri ya mapulogalamu ogwiritsira ntchito, omwe angathe kukwaniritsa zofunikira za kukonzanso mankhwala ndi kuwonjezera zinthu zatsopano;

5. Zizindikiro zonse zoyimitsidwa mwadzidzidzi za dongosolo lonse lolamulira ndi zizindikiro zotetezera chitetezo pakati pa zipangizo zogwirira ntchito ndi ma robot zimagwirizanitsidwa ndi dongosolo la chitetezo ndipo kuwongolera kotsekedwa kumayendetsedwa kudzera mu pulogalamu yolamulira;

6. Dongosolo loyang'anira limazindikira kugwirizana kwazizindikiro pakati pa zida zogwirira ntchito monga ma robot, kutsitsa ma silos, tongs ndi zida zamakina;

7. Makina a zida zamakina amayenera kuzindikira kusinthana kwa ma siginecha ndi makina a loboti.

Processing Machine Tool (yoperekedwa ndi wosuta)

1. Chida cha makina opangira makina chidzakhala ndi makina ochotsa tchipisi (kapena kuyeretsa tchipisi tachitsulo pamanja komanso pafupipafupi) komanso kutsegulira ndi kutseka kwachitseko (ngati pali kutsegula ndi kutseka kwa makina);

2. Pa ntchito makina chida, tchipisi chitsulo saloledwa kukulunga workpieces, zomwe zingakhudze clamping ndi kuika workpieces ndi maloboti;

3. Poganizira za kuthekera kwa zinyalala za chip kugwera mu nkhungu ya chida cha makina, Party B imawonjezera ntchito yowomba mpweya ku tongs za robot.

4. Party A idzasankha zida zoyenera kapena teknoloji yopangira kuti iwonetsetse moyo wa zida zogwiritsira ntchito kapena kusintha zida ndi chosinthira chida mkati mwa chida cha makina, kuti asasokoneze khalidwe la makina opangira makina chifukwa cha kuvala kwa zida.

5. Kuyankhulana kwa chizindikiro pakati pa chida cha makina ndi robot kudzayendetsedwa ndi Party B, ndipo Party A idzapereka zizindikiro zoyenera za chida cha makina monga momwe zikufunikira.

6. Loboti imayendetsa movutikira posankha zigawozo, ndipo chida cha makinawo chimazindikira malo enieniwo malinga ndi malo ogwiritsira ntchito.

Chitetezo mpanda

1. Khazikitsani mpanda wodzitchinjiriza, chitseko chachitetezo, loko yotchingira ndi zida zina, ndikuchita chitetezo chofunikira cholumikizirana.

2. Khomo lachitetezo lidzakhazikitsidwa pamalo oyenera a mpanda wachitetezo. Zitseko zonse ziyenera kukhala ndi zosinthira chitetezo ndi batani, batani lokonzanso ndi batani loyimitsa mwadzidzidzi.

3. Khomo lachitetezo limalumikizidwa ndi dongosolo kudzera pachitetezo chachitetezo (kusintha). Chitseko cha chitetezo chikatsegulidwa mosadziwika bwino, dongosolo limayima ndikupereka alamu.

4. Njira zotetezera chitetezo zimatsimikizira chitetezo cha ogwira ntchito ndi zida kudzera pa hardware ndi mapulogalamu.

5. Mpanda wachitetezo ukhoza kuperekedwa ndi Party A mwiniwake. Ndikofunikira kuwotcherera ndi gululi wapamwamba kwambiri ndikupenta ndi varnish yachikasu yochenjeza pamwamba.

Chitetezo mpanda

Chitetezo loko

Mpanda wachitetezo Malo ogwirira ntchito (operekedwa ndi Party A)

| Magetsi | Magetsi: magawo atatu a mawaya a AC380V ± 10%, kusinthasintha kwamagetsi ± 10%, mafupipafupi: 50HZ; Mphamvu ya kabati yolamulira loboti idzakhala ndi makina odziyimira pawokha; Kabati yoyang'anira maloboti iyenera kukhazikitsidwa ndi kukana kwapansi pansi pa 10Ω;Mtunda wabwino pakati pa gwero lamagetsi ndi kabati yowongolera magetsi ya robot uyenera kukhala mkati mwa 5 metres. |

| Gwero la mpweya | Mpweya woponderezedwa udzasefedwa m'madzi, gasi ndi zonyansa, ndipo mphamvu yotulutsa pambuyo podutsa FRL idzakhala 0.5 ~ 0.8Mpa; Mtunda wabwino pakati pa gwero la mpweya ndi thupi la loboti uyenera kukhala mkati mwa 5 metres. |

| Maziko | Kuchitira ndi ochiritsira pansi simenti pansi pa msonkhano wa Party A, ndi unsembe m'munsi pa aliyense chipangizo adzakhala atakhazikika pansi ndi mabawuti kuwonjezera; Mphamvu ya konkire: 210 kg / cm2; Makulidwe a konkire: Kuposa 150 mm;Kusagwirizana kwa maziko: Ochepera ± 3mm. |

| Mikhalidwe Yachilengedwe | Kutentha kozungulira: 0 ~ 45 ℃; chinyezi wachibale: 20% ~ 75% RH (palibe condensation amaloledwa); Kuthamanga kwa vibration: Pansi pa 0.5G. |

| Zosiyanasiyana | Pewani mpweya woyaka ndi zowononga komanso zamadzimadzi, ndipo musawaze mafuta, madzi, fumbi, ndi zina; Osayandikira komwe kumachokera phokoso lamagetsi. |