Zofunikira za Pulojekiti

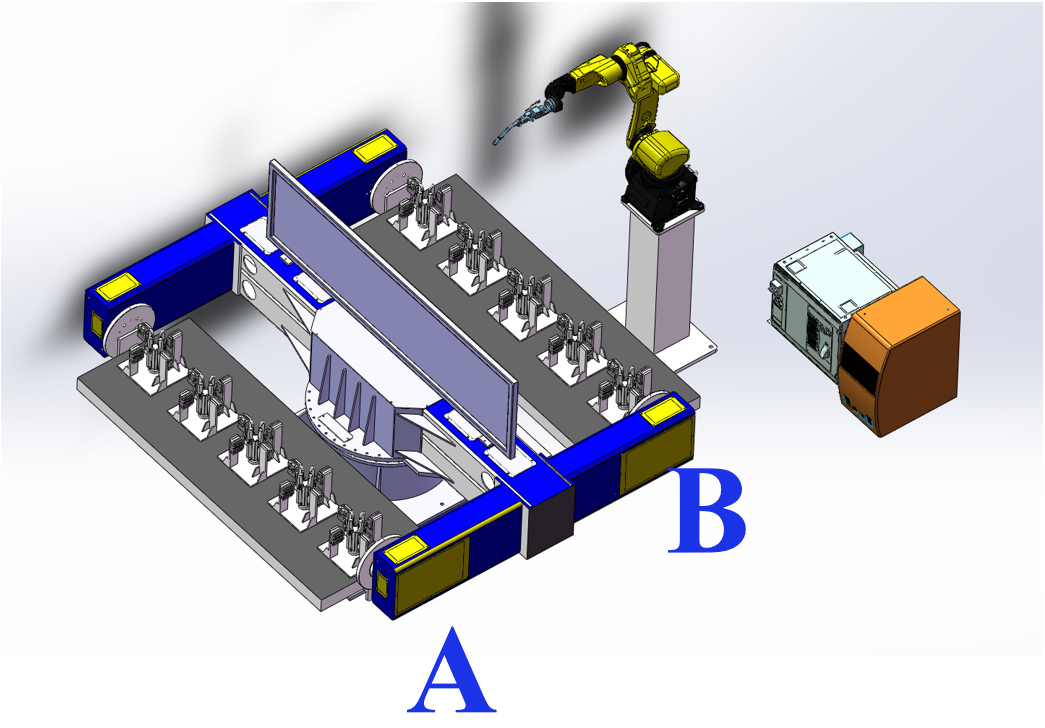

Mapangidwe Onse & 3D Model

Zindikirani: Chiwonetserochi chimangogwiritsidwa ntchito pojambula masanjidwe ndipo sichikuyimira mawonekedwe a zida. Kukula kwapadera kudzatsimikiziridwa malinga ndi malo a kasitomala.

Chojambula chakuthupi & mtundu wa 3D

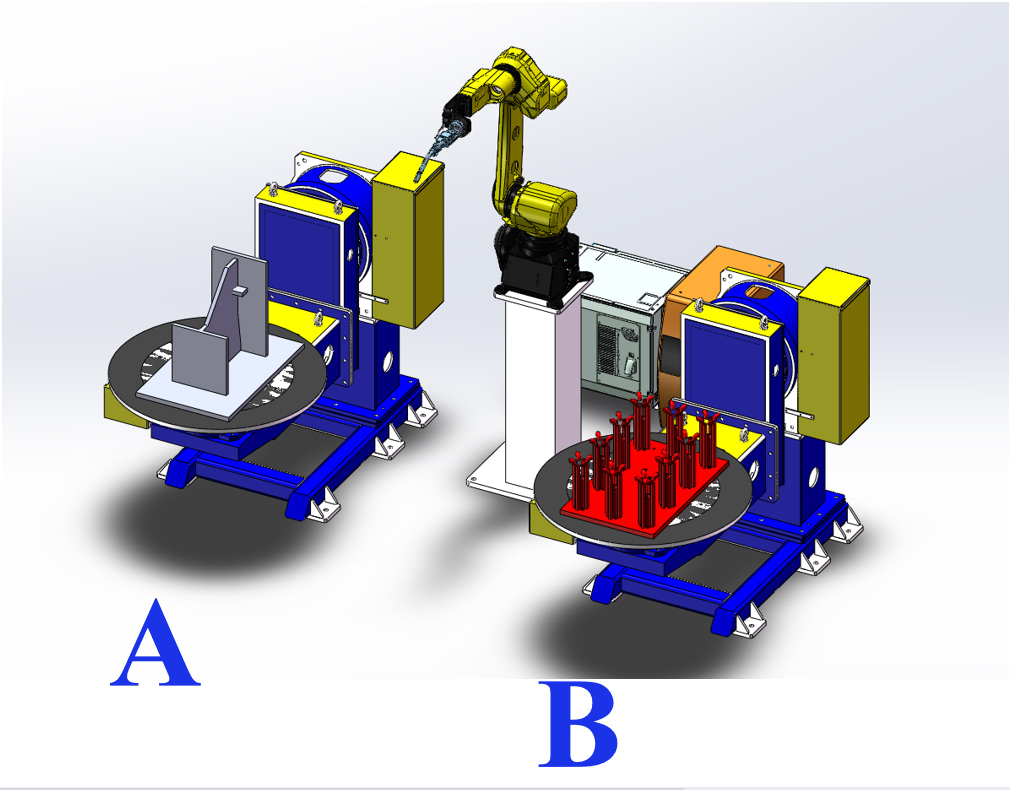

Zojambula zakuthupi & mtundu wa 3D

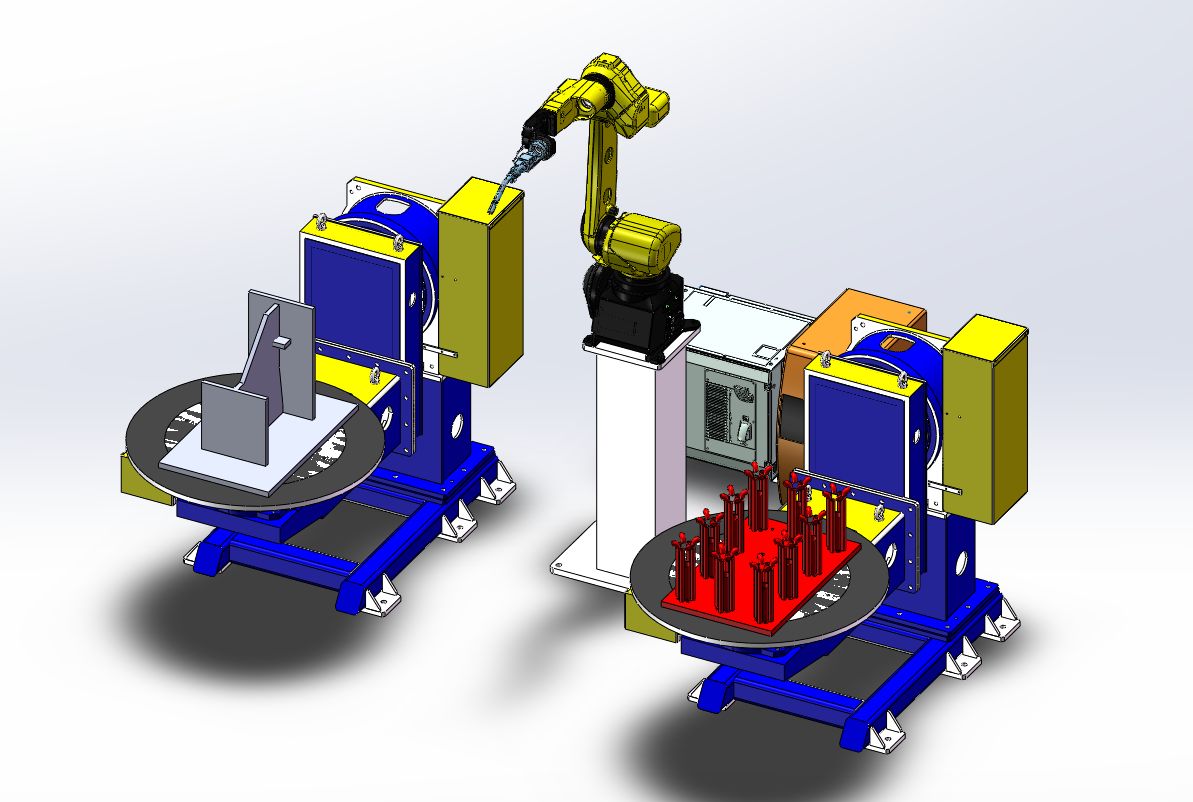

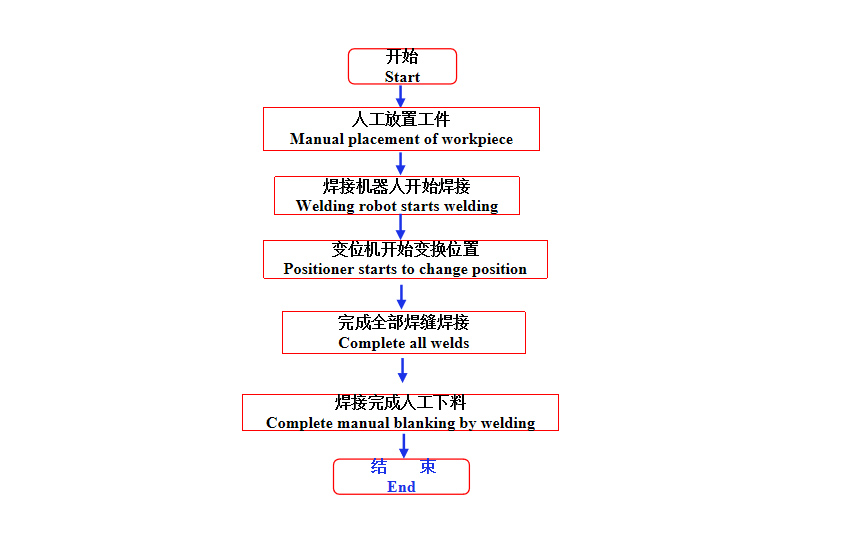

Kayendedwe kantchito

Zoyenera kugwira ntchito

(1) Ikani pamanja workpiece mu positioner ndi kukonza malinga ndi zofunika.

(2) Zida zonse zikayatsidwa ndipo palibe alamu yomwe ikuwonetsedwa, konzekerani kukhazikitsa.

(3) Loboti imayima pa chiyambi cha ntchito, ndipo pulogalamu yoyendetsera loboti ndiye pulogalamu yofananira yopanga.

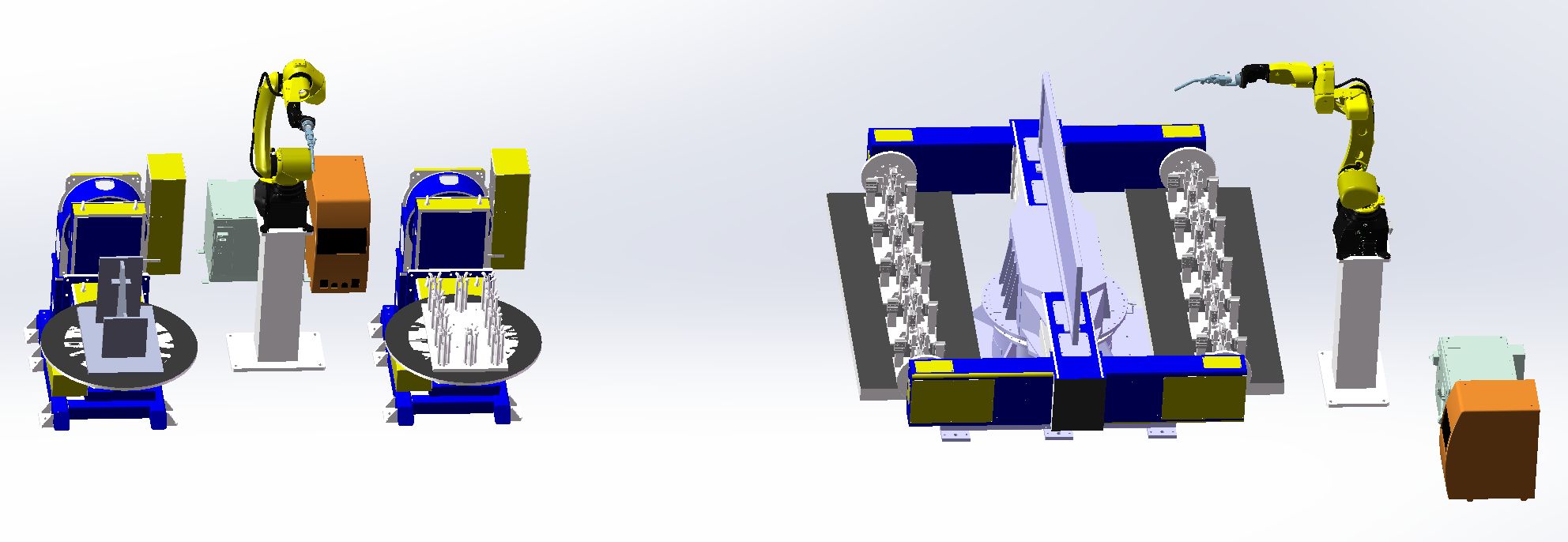

Njira yowotcherera ya sleeve subassembly

1. Ikani pamanja ma seti asanu a zida za manja kumbali A.

2. Bwererani kudera lachitetezo pamanja ndikuyamba batani loletsa silinda kuti mumitse workpiece.

3. Choyikapo chimazungulira mpaka loboti yomwe ili kumbali B iyamba kuwotcherera.

4. Chotsani pamanja zida zowotcherera mbali A, ndiyeno magulu asanu a ng'oma.

5. Yendetsani mozungulira maulalo omwe ali pamwambapa.

Nthawi yowotcherera pamtundu uliwonse wa manja ndi 3min (kuphatikiza nthawi yoyika), ndipo nthawi yowotcherera ya seti 10 ndi 30min.

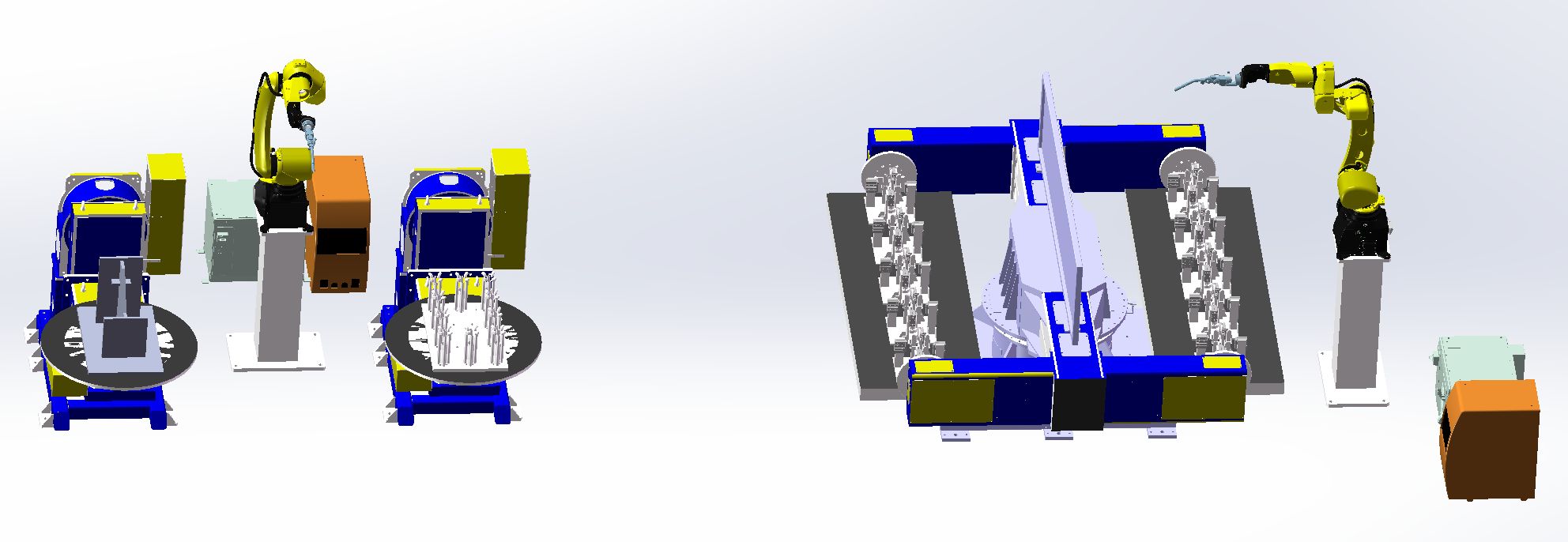

Njira yowotcherera ya msonkhano wophatikizidwa wa mbale + msonkhano wa manja

1. Ikirani pamanja mbale yoyikapo cholozeratu pa choyimira chamtundu wa L kumbali A.

2. Yambani batani loboti kuwotcherera ophatikizidwa mbale msonkhano (15min/set). 3.

3. Ikani pamanja mbali zomasuka za gulu la manja pa choyimira chamtundu wa L kumbali B.

4. Loboti ipitiliza kuwotcherera mawotchi pambuyo pakuwotcherera mbale (kuwotcherera manja kwa 10min + kuyika pamanja kwa chogwirira ntchito ndi kuwotcherera maloboti kwa mphindi 5)

5. Chotsani ophatikizidwa mbale msonkhano pamanja.

6. Kuwotcherera pamanja kwa ophatikizidwa mbale msonkhano (kuchotsa malo kuwotcherera-kutsegula mkati 15min)

7. Ikirani pamanja mbale yoyikapo yoyikidwapo pa choyimira chamtundu wa L kumbali A.

8. Chotsani msonkhano wa ma welded sleeve ndikuyika zida zosinthira

9. Yendetsani kagwiritsidwe ntchito ka maulalo omwe ali pamwambapa.

Nthawi yomaliza kuwotcherera mbale yophatikizidwa ndi 15min + nthawi yomaliza yolumikizira manja ndi 15min.

Nthawi yonse 30min

Kuyambitsa kwa Tong Changing Chipangizo

Nthawi yowotcherera ya robot pa kugunda komwe tatchula pamwambapa ndikokwanira kwambiri popanda kuyimitsa. Malinga ndi maola 8 patsiku ndi ogwira ntchito awiri, kutulutsa kwamisonkhano iwiri kumakhala ma seti 32 patsiku.

Kuti muwonjezere zotsatira:

Loboti imodzi imawonjezedwa ku malo okwera atatu pa station subassembly station ndikusinthidwa kukhala makina owotcherera pawiri. Nthawi yomweyo, malo ophatikizira ma mbale ophatikizira + manja amafunikiranso kuwonjezera ma seti awiri amtundu wa L ndi seti imodzi ya loboti. Patsiku la maola 8 ndi operekera atatu, zotulutsa zamagulu awiri zimakwana ma seti 64 patsiku.

Mndandanda wa Zida

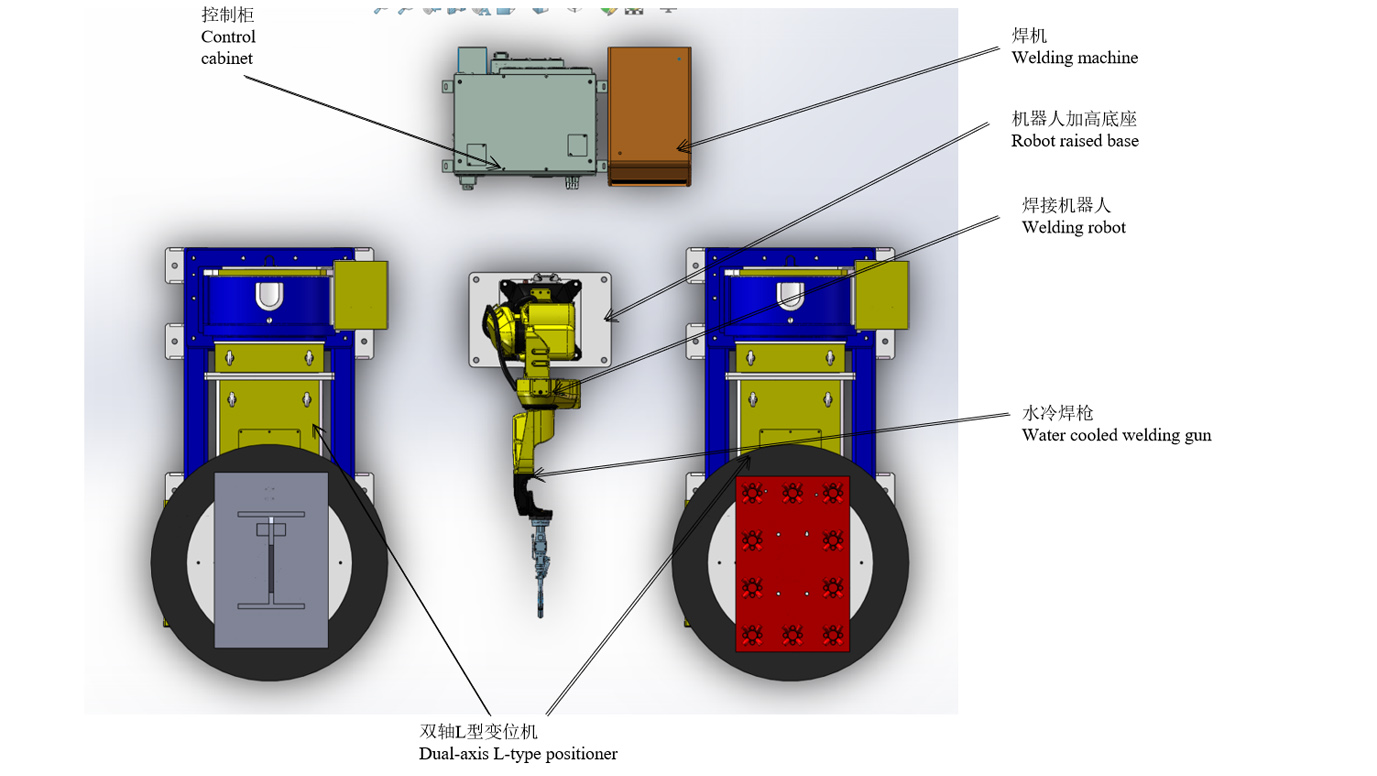

| Kanthu | S/N | Dzina | Qty. | MALANGIZO |

| Maloboti | 1 | RH06A3-1490 | 2 seti | Zoperekedwa ndi Chen Xuan |

| 2 | Kabati yowongolera ma robot | 2 seti | ||

| 3 | Maloboti adakweza maziko | 2 seti | ||

| 4 | Madzi utakhazikika kuwotcherera mfuti | 2 seti | ||

| Zida zozungulira | 5 | Gwero la Mphamvu Yowotcherera MAG-500 | 2 seti | Zoperekedwa ndi Chen Xuan |

| 6 | Malo amtundu wa L wapawiri-axis | 2 seti | ||

| 7 | Choyika chozungulira cha ma axis atatu chopingasa | 1 seti | Zoperekedwa ndi Chen Xuan | |

| 8 | Kusintha | 1 seti | ||

| 9 | Wotsuka Mfuti | Khalani | Zosankha | |

| 10 | Zida zochotsera fumbi | 2 seti | ||

| 11 | Chitetezo mpanda | 2 seti | ||

| Ntchito Yogwirizana | 12 | Kuyika ndi kutumiza | 1 chinthu | |

| 13 | Kuyika ndi Mayendedwe | 1 chinthu | ||

| 14 | Maphunziro aukadaulo | 1 chinthu |

Kufotokozera zaukadaulo

Mfuti yowotcherera yomangidwa m'madzi

1) Mfuti iliyonse yowotcherera idzadutsa muyeso wa ternary kuti iwonetsetse kuti ikulondola;

2) Mbali ya R ya mfuti yowotcherera imapangidwa ndi njira yonyowa yoponyera sera, yomwe sidzawonongeka chifukwa cha kutentha kwakukulu kopangidwa ndi kuwotcherera;

3) Ngakhale mfuti yowotcherera itagundana ndi chogwirira ntchito ndi zida zogwirira ntchito, mfuti yowotcherera sidzapindika ndipo palibe kuwongolera komwe kumafunikira;

4) Kupititsa patsogolo mphamvu ya rectifier ya mpweya woteteza;

5) Kulondola kwa mbiya imodzi kuli mkati mwa 0.05;

6) Chithunzicho ndi chongotanthauza, ndipo chikuyenera kusankha komaliza.

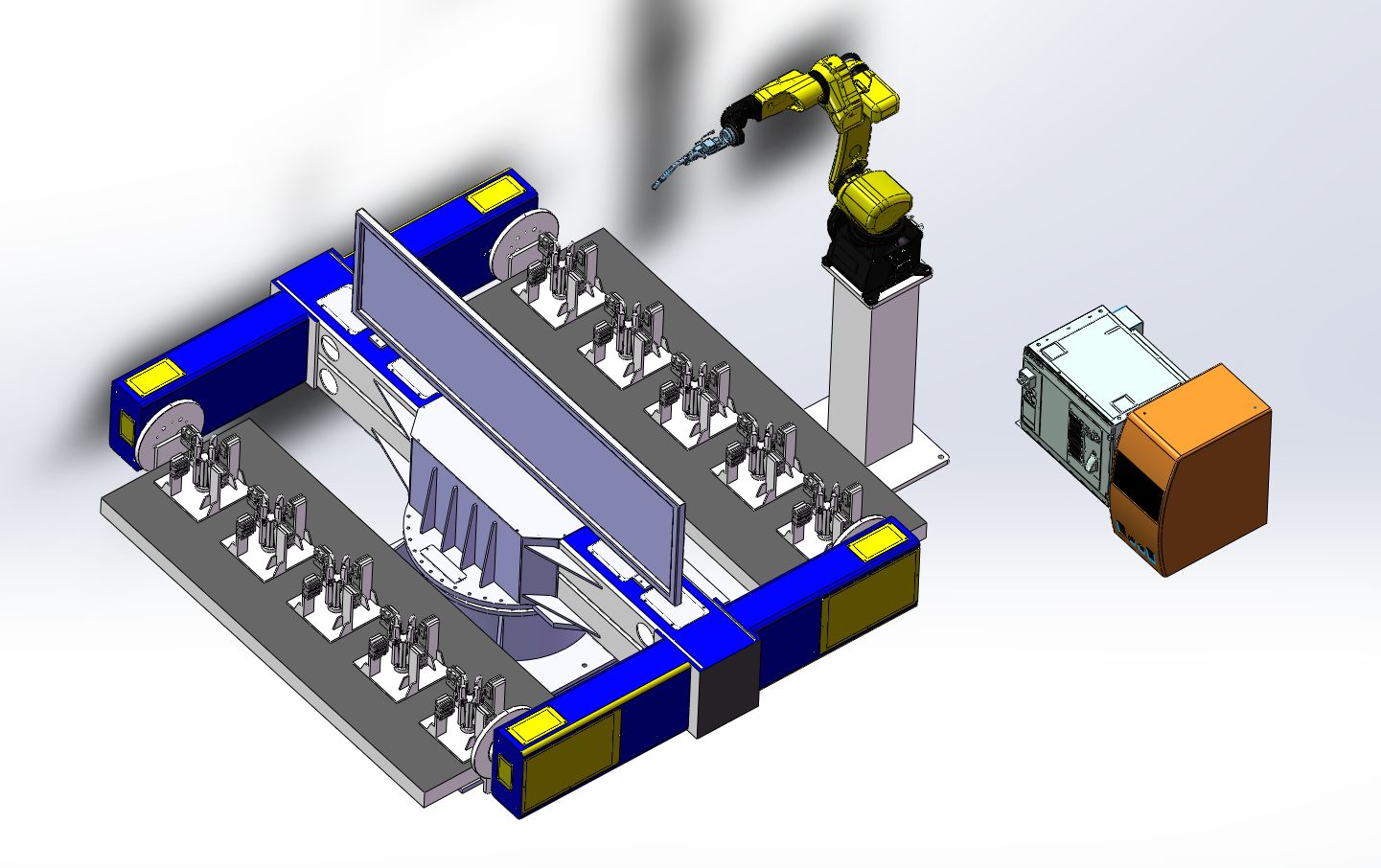

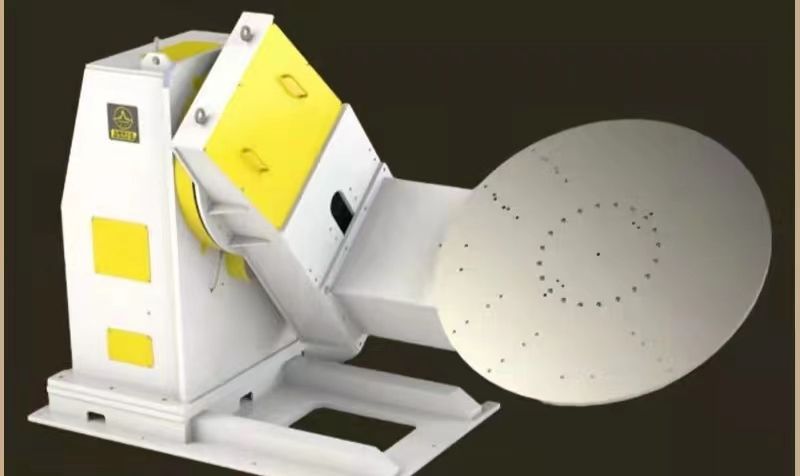

Malo amtundu wa L wapawiri-axis

Positioner ndi chida chapadera chowotcherera chothandizira, chomwe ndi choyenera kuwotcherera kusamutsidwa kwa ntchito yozungulira, kuti mupeze malo abwino opangira makina ndi liwiro lawotcherera. Itha kugwiritsidwa ntchito ndi manipulator ndi kuwotcherera makina kuti apange malo owotcherera okha, komanso itha kugwiritsidwanso ntchito pakusamutsidwa kwa workpiece pakugwira ntchito pamanja. Kutulutsa kosinthika komwe kumakhala ndi ma frequency-frequency drive kumatengera kasinthasintha wa workbench, ndikuwongolera mwachangu kwambiri. Bokosi lowongolera lakutali limatha kuzindikira magwiridwe antchito akutali a workbench, komanso limatha kulumikizidwa ndi makina owongolera ndi kuwotcherera makina kuti azindikire ntchito yolumikizidwa. Chowotcherera poyikapo nthawi zambiri chimakhala ndi makina ozungulira komanso njira yosinthira ya benchi yogwirira ntchito. The workpiece atakhazikika pa workbench akhoza kufika kuwotcherera chofunika ndi msonkhano ngodya mwa kukweza, kutembenuka ndi kasinthasintha workbench. The workbench atembenuza mu variable pafupipafupi stepless liwiro malamulo, amene angapeze wokhutiritsa kuwotcherera liwiro.

Zithunzi ndi zongonena zokha, ndipo zikuyenera kupangidwa komaliza.

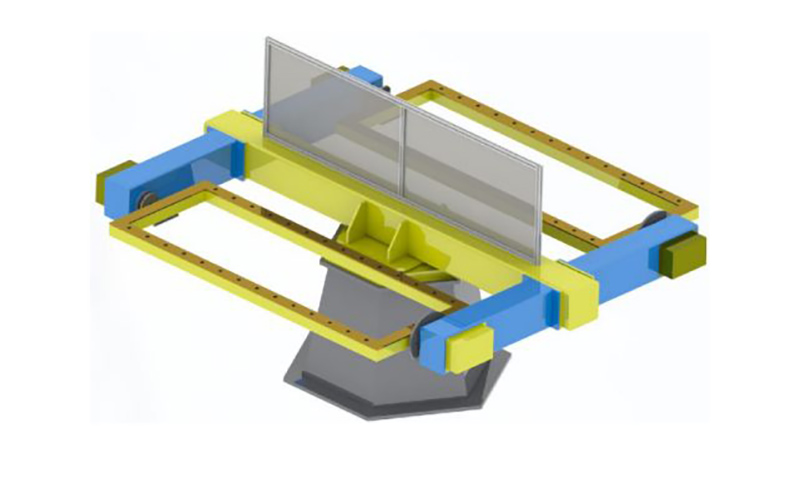

Choyika chozungulira cha ma axis atatu chopingasa

1) Malo ozungulira ozungulira atatu opingasa amapangidwa makamaka ndi maziko okhazikika, bokosi lozungulira lozungulira ndi bokosi la mchira, chimango chowotcherera, servo mota ndi chochepetsera molondola, makina oyendetsa, chivundikiro choteteza ndi makina owongolera magetsi, ndi zina zambiri.

2) Pokonza ma servo motors osiyanasiyana, choyikapo chikhoza kuyendetsedwa patali kudzera mwa mphunzitsi wa robot kapena bokosi la ntchito lakunja;

3) The kuwotcherera chofunika ndi msonkhano ngodya zimatheka ndi kutembenuza workpiece atakhazikika pa workbench;

4) The kasinthasintha wa workbench amawongoleredwa ndi servo galimoto, amene angathe kukwaniritsa bwino kuwotcherera liwiro;

5) Zithunzi ndizongofotokozera zokha, ndipo zimangopangidwa komaliza;

Kuwotcherera magetsi

Ndioyenera kuphatikizira, kupukutira, kuphatikizira pamakona, cholumikizira cha chubu, cholumikizira mizere ndi mitundu ina yolumikizana, ndipo imatha kuzindikira kuwotcherera kulikonse.

Chitetezo ndi kudalirika

Makina owotchera ndi mawaya odyetsa amakhala ndi chitetezo chopitilira pano, champhamvu kwambiri komanso kutentha kwambiri. Adapambana mayeso a EMC ndi magwiridwe antchito amagetsi omwe amafunidwa ndi muyezo wadziko lonse wa GB/T 15579, ndipo adapereka chiphaso cha 3C kuti awonetsetse kudalirika komanso chitetezo chomwe chikugwiritsidwa ntchito.

Kuteteza mphamvu ndi kuteteza chilengedwe

Nthawi yodziwira gasi, nthawi yoperekera gasi ndi nthawi yoperekera gasi yocheperako zimasinthidwa kuti zitsimikizire kugwiritsa ntchito bwino kwa gasi. Pamene makina owotcherera ndi mphamvu, ngati salowa m'malo kuwotcherera mkati mphindi 2 (nthawi chosinthika), izo basi kulowa m'tulo. Zimitsani fani ndikuchepetsa kugwiritsa ntchito mphamvu.

Chithunzicho ndi chongotengera kokha, ndipo chikuyenera kusankha chomaliza.

Kuwotcherera magetsi

Kuyeretsa mfuti ndi chipangizo chopopera mafuta cha silicone ndi chida chodulira waya

1) Silicone mafuta kupopera chipangizo pa siteshoni mfuti kuyeretsa utenga nozzle awiri kupopera mtanda mtanda, kotero kuti silikoni mafuta akhoza kufika pamwamba pamwamba pa kuwotcherera tochi nozzle bwino ndi kuonetsetsa kuti kuwotcherera slag si kumamatira pa nozzle.

2) Kuyeretsa mfuti ndi zida zopopera mafuta za silicone zimapangidwa pamalo omwewo, ndipo loboti imatha kumaliza ntchito yopopera mafuta a silicone ndi kuyeretsa mfuti ndi chinthu chimodzi chokha.

3) Pankhani ya kuwongolera, kuyeretsa mfuti ndi kupopera mafuta kwa silikoni kumangofunika chizindikiro choyambira, ndipo kumatha kuyambika molingana ndi zomwe zachitika.

4) Chida chodulira mawaya chimagwiritsa ntchito njira yodzipangira yokhayokha yamfuti yowotcherera, yomwe imathetsa kufunika kogwiritsa ntchito ma valve a solenoid kuti aziwongolera ndikuwongolera kuwongolera kwamagetsi.

5) Chida chodulira waya chikhoza kukhazikitsidwa padera kapena kuikidwa pamfuti yotsuka ndi silicone yopopera mafuta kuti ipange chipangizo chophatikizika, chomwe sichimangopulumutsa malo osungiramo, komanso chimapangitsa makonzedwe ndi kuwongolera njira ya gasi kukhala kosavuta.

6) Chithunzicho ndi chongotanthauza, ndipo chikuyenera kusankha komaliza.

Chitetezo mpanda

1. Khazikitsani mipanda yoteteza, zitseko zachitetezo kapena ma gratings otetezedwa, maloko otetezedwa ndi zida zina, ndikuchita chitetezo chotchinga chofunikira.

2. Khomo lachitetezo lidzakhazikitsidwa pamalo oyenera a mpanda woteteza. Zitseko zonse ziyenera kukhala ndi masiwichi otetezeka ndi mabatani, batani lokonzanso ndi batani loyimitsa mwadzidzidzi.

3. Khomo lachitetezo limalumikizidwa ndi dongosolo kudzera pachitetezo chachitetezo (kusintha). Chitseko cha chitetezo chikatsegulidwa mosadziwika bwino, dongosolo limasiya kugwira ntchito ndikupereka alamu.

4. Njira zotetezera chitetezo zimatsimikizira chitetezo cha ogwira ntchito ndi zida kudzera pa hardware ndi mapulogalamu.

5. Mpanda wachitetezo ukhoza kuperekedwa ndi Party A yokha. Ndibwino kuti mugwiritse ntchito kuwotcherera gululi wapamwamba kwambiri ndikuphika utoto wachikasu wochenjeza pamwamba.

Electrical Control System

1. Zimaphatikizapo kulamulira dongosolo ndi kuyankhulana chizindikiro pakati pa zipangizo, kuphatikizapo masensa, zingwe, mipata, masiwichi, etc.;

2. Chigawo chodziwikiratu chimapangidwa ndi kuwala kwamitundu itatu. Panthawi yogwira ntchito bwino, kuwala kwamitundu itatu kumawonetsa zobiriwira; ngati unit ikulephera, kuwala kwamitundu itatu kudzawonetsa alamu yofiira pakapita nthawi;

3. Pali mabatani oyimitsa mwadzidzidzi pa kabati yowongolera ma robot ndi bokosi lophunzitsira. Pakachitika mwadzidzidzi, batani loyimitsa mwadzidzidzi likhoza kukanidwa kuti lizindikire kuyimitsidwa kwadzidzidzi kwadongosolo ndikutumiza chizindikiro cha alamu nthawi yomweyo;

4. Mapulogalamu osiyanasiyana ogwiritsira ntchito amatha kupangidwa kudzera mu chipangizo chophunzitsira, mapulogalamu ambiri akhoza kupangidwa, omwe angathe kukwaniritsa zofunikira za kukonzanso mankhwala ndi zatsopano;

5. Zizindikiro zonse zoyimitsa mwadzidzidzi za dongosolo lonse lolamulira ndi zizindikiro zotetezera chitetezo pakati pa zipangizo zopangira ndi ma robot zimagwirizanitsidwa ndi dongosolo la chitetezo ndipo zimagwirizanitsidwa kudzera mu pulogalamu yolamulira;

6. Dongosolo lowongolera limazindikira kugwirizana kwa chizindikiro pakati pa zida zogwirira ntchito monga robot, bin yonyamula, gripper ndi zida zopangira makina.

7. Makina a zida zamakina amayenera kuzindikira kusinthana kwa ma siginecha ndi makina a loboti.

Malo ogwirira ntchito (operekedwa ndi Party A)

| Magetsi | Mphamvu yamagetsi: magawo atatu mawaya anayi AC380V ± 10%, kusinthasintha kwamagetsi ± 10%, pafupipafupi: 50Hz; Mphamvu yamagetsi ya kabati yowongolera ma robot imayenera kukhala ndi switch yodziyimira payokha; Kabati yoyang'anira maloboti iyenera kukhazikitsidwa ndi kukana kwapansi pansi pa 10Ω; Mtunda wabwino pakati pa magetsi ndi nduna yamagetsi ya robot ndi mkati mwa 5 mamita. |

| Gwero la mpweya | Mpweya woponderezedwawo udzasefedwa kuti uchotse chinyezi ndi zonyansa, ndipo mphamvu yotulutsa pambuyo podutsa katatu iyenera kukhala 0.5 ~ 0.8Mpa; Mtunda wabwino pakati pa gwero la mpweya ndi thupi la robot uli mkati mwa 5 mamita. |

| Maziko | Pansi wamba simenti pansi pa msonkhano wa Party A adzagwiritsidwa ntchito pochiza, ndipo zoyikapo za chipangizo chilichonse zidzakhazikika pansi ndi mabawuti okulitsa; Mphamvu ya konkriti: 210 kg / cm 2; makulidwe a konkire: wamkulu kuposa 150 mm; Kusagwirizana kwa maziko: zosakwana ± 3mm. |

| Mikhalidwe Yachilengedwe | Kutentha kwapakati: 0 ~ 45 ° C; Wachibale chinyezi: 20% ~ 75% RH (palibe condensation); Kuthamanga kwa vibration: zosakwana 0.5G |

| Zina | Pewani mpweya woyaka ndi zowononga komanso zamadzimadzi, ndipo musawaze mafuta, madzi, fumbi, ndi zina; Khalani kutali ndi magwero a phokoso lamagetsi. |