Njira Analysis ya Production Line

Die retrorei im technischen prozess

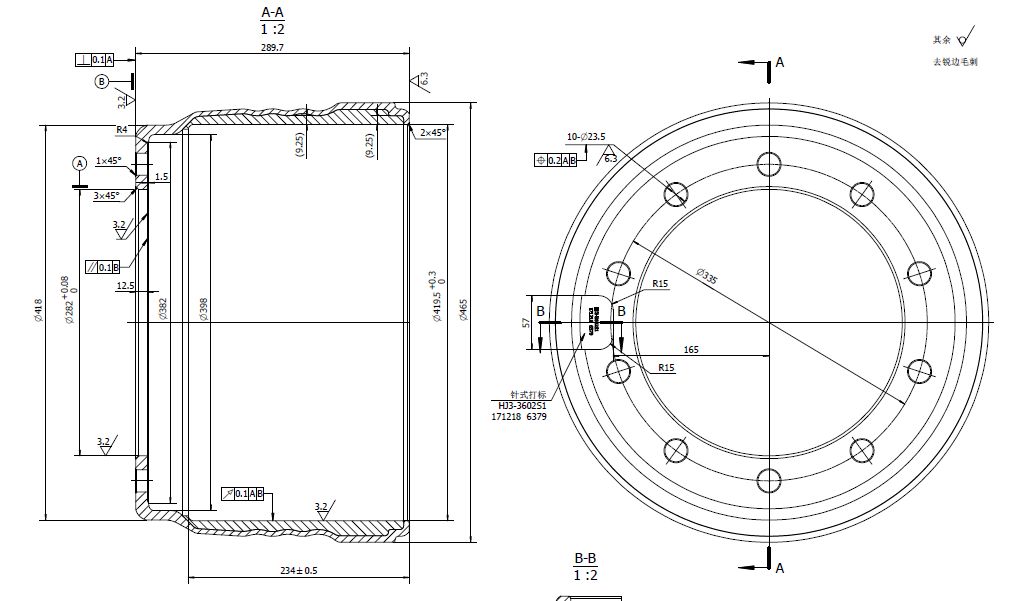

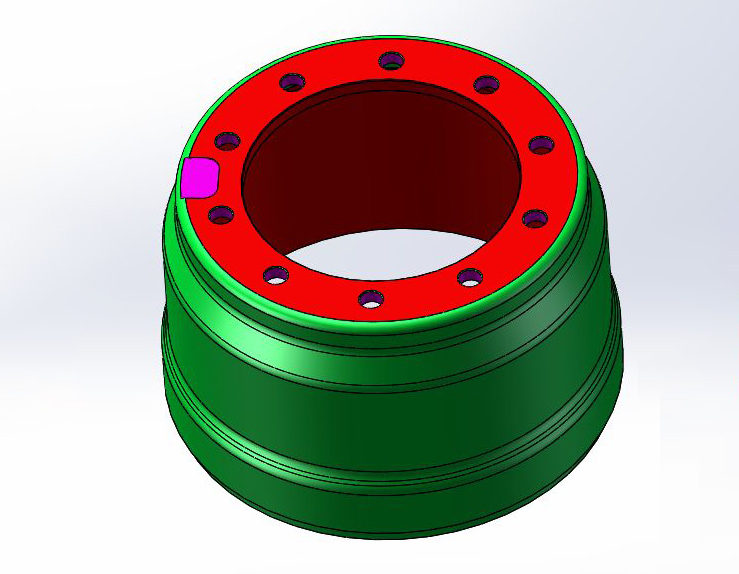

1. The disposable clamping process imatengedwa panthawi yotembenuka. Kutembenuza mbali zonse Machining, kuphatikizapo pansi pamwamba pa workpieces.

2. Pobowola, ma hydraulic clamps adzagwiritsidwa ntchito kuti apeze ndi m'mimba mwake wa Φ282 ndi kumtunda kwa nkhope, kubowola 10-Φ23.5 dzenje ndi chamfering mbali zonse ziwiri, ndi mphero malo osindikizira a pneumatic;

Mndandanda wa Zida

| OP10 Machining Cycle timer | |||||||||||||||

| Kufotokozera Njira |

| ||||||||||||||

| Makasitomala | Zida zogwirira ntchito | 45 | Chitsanzo cha chida cha makina | Archive No. | |||||||||||

| Dzina lazogulitsa | Kudula chida kutsinde welded mbali | Chojambula No. | Tsiku lokonzekera | 2021.1.19 | Okonza | ||||||||||

| Njira sitepe | Mpeni No. | makina okhutira | Dzina lachida | Kudula Diameter | Kudula liwiro | Liwiro lozungulira | Chakudya pa kusintha | kudyetsa ndi chida makina | Chiwerengero cha cuttings | Njira iliyonse | Machining nthawi | Idle Time | Limbani ndi kumasula | Chida chosintha nthawi | |

| Ayi. | Ayi. | Desoriptions | Zida | D mm | VcM/mphindi | R pm | mm / Rev | mm/Mphindi | Nthawi | Utali mm | Sec | Sec | Sec | ||

| 1 | T01 | Dulani mbali ya kumtunda pafupi | 455.00 | 450 | 315 | 0.35 | 110 | 1 | 20.0 | 10.89 | 3 | 3 | |||

| 2 | T02 | Lathe pafupifupi DIA 419.5 zamkati, DIA 382 step face ndi DIA 282 zamkati | 419.00 | 450 | 342 | 0.35 | 120 | 1 | 300.0 | 150.36 | 3 | 3 | |||

| 3 | T03 | Dulani kumapeto kwenikweni | 455.00 | 450 | 315 | 0.25 | 79 | 1 | 20.0 | 15.24 | 3 | ||||

| 4 | T04 | Lathe ndendende DIA 419.5 zamkati, DIA 382 step face ndi DIA 282 zamkati | 369.00 | 450 | 388 | 0.25 | 97 | 1 | 300. 0 | 185.39 | |||||

| 5 | T05 | Latheni mozungulira ndi pafupifupi kumunsi kumapeto kwa nkhope | 390.00 | 420 | 343 | 0.35 | 120 | 1 | 65.0 | 32.49 | 3 | ||||

| 6 | T06 | Lathe mosintha ndi ndendende m'munsi kumapeto kwa nkhope | 390.00 | 450 | 367 | 0.25 | 92 | 1 | 65.0 | 42.45 | 3 | ||||

| Kufotokozera: | Nthawi yodula: | 437 | Chachiwiri | Nthawi yokhomerera ndi fixture komanso kutsitsa ndi kusalemba zinthu: | 15.00 | Chachiwiri | |||||||||

| Nthawi Yothandizira: | 21 | Chachiwiri | Maola onse opangira makina: | 472.81 | Chachiwiri | ||||||||||

| OP20 Machining Cycle timer | |||||||||||||||

| Kufotokozera Njira |  | ||||||||||||||

| Makasitomala | Zida zogwirira ntchito | Mtengo wa HT250 | Chitsanzo cha chida cha makina | Archive No. | |||||||||||

| Dzina lazogulitsa | Ng'oma yonyema | Chojambula No. | Tsiku lokonzekera | 2021.1.19 | Okonza | ||||||||||

| Njira sitepe | Mpeni No. | makina okhutira | Dzina lachida | Kudula Diameter | Kudula liwiro | Liwiro lozungulira | Chakudya pa kusintha | kudyetsa ndi chida makina | Chiwerengero cha cuttings | Njira iliyonse | Machining nthawi | Idle Time | Limbani ndi kumasula | Chida chosintha nthawi | |

| Ayi. | Ayi. | Desoriptions | Zida | D mm | VcM/mphindi | R pm | mm / Rev | mm/Mphindi | Nthawi | Utali mm | Sec | Sec | Sec | ||

| 1 | T01 | Dulani dzenje la 10-DIA 23.5 | Kubowola pansi pa dzenje DIA 23.5 | 23.50 | 150 | 2033 | 0.15 | 305 | 10 | 15.0 | 29.52 | 20 | 5 | ||

| 2 | T04 | 10-DIA 23 Orifice Chamfering | DIA 30 pawiri reaming chamfering cutter | 30.00 | 150 | 1592 | 0.20 | 318 | 10 | 3.0 | 6.65 | 20 | 5 | ||

| 3 | T06 | 10-DIA 23.5 Back orifice chamfering | DIA 22 reverse chamfering cutter | 22.00 | 150 | 2171 | 0.20 | 434 | 10 | 3.0 | 4.14 | 40 | 5 | ||

| 4 | T08 | Malo Osindikizira Mtsinje | DIA 30 lalikulu mapewa mphero | 30.00 | 80 | 849 | 0.15 | 127 | 1 | 90.0 | 42.39 | 4 | 5 | ||

| Kufotokozera: | Nthawi yodula: | 82 | Chachiwiri | Nthawi yokhomerera ndi fixture komanso kutsitsa ndi kusalemba zinthu: | 30 | Chachiwiri | |||||||||

| Nthawi Yothandizira: | 104 | Chachiwiri | Maola onse opangira makina: | 233.00 | Chachiwiri | ||||||||||

Chiyambi cha Production Line

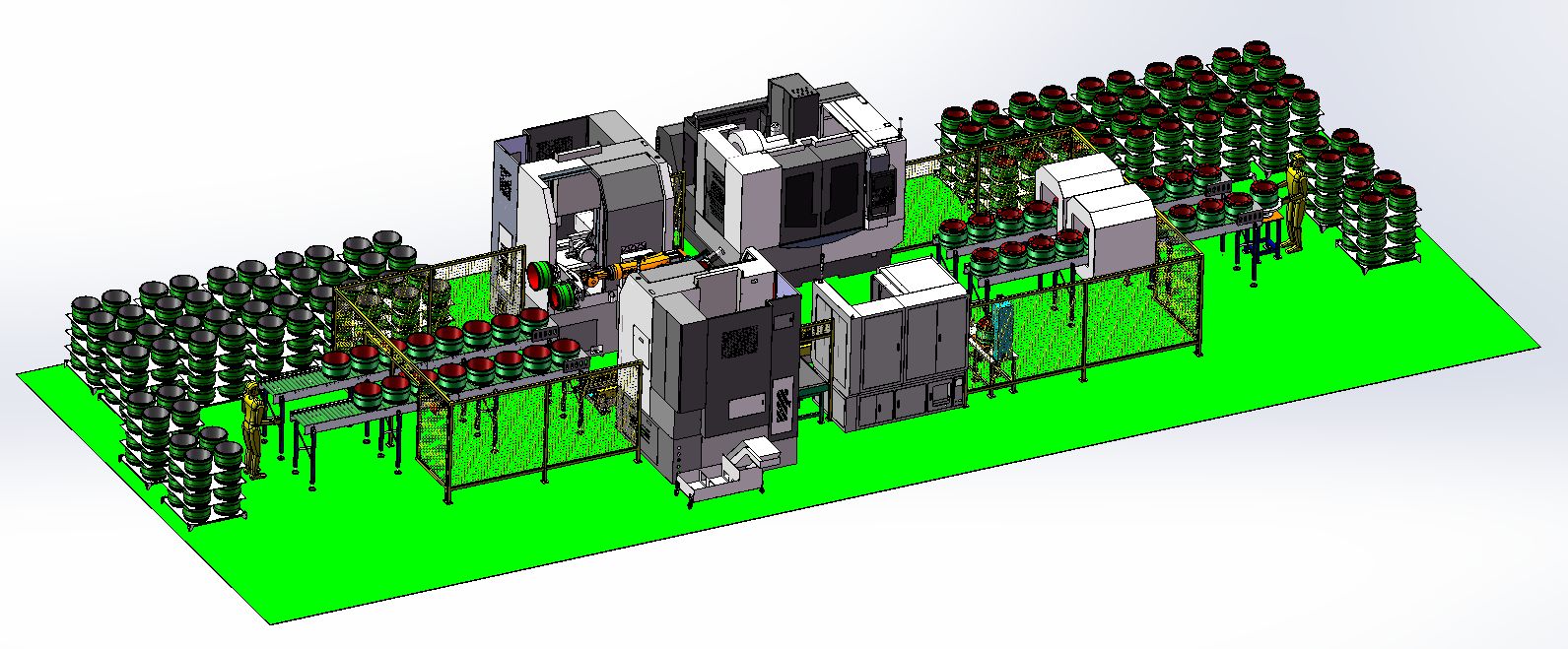

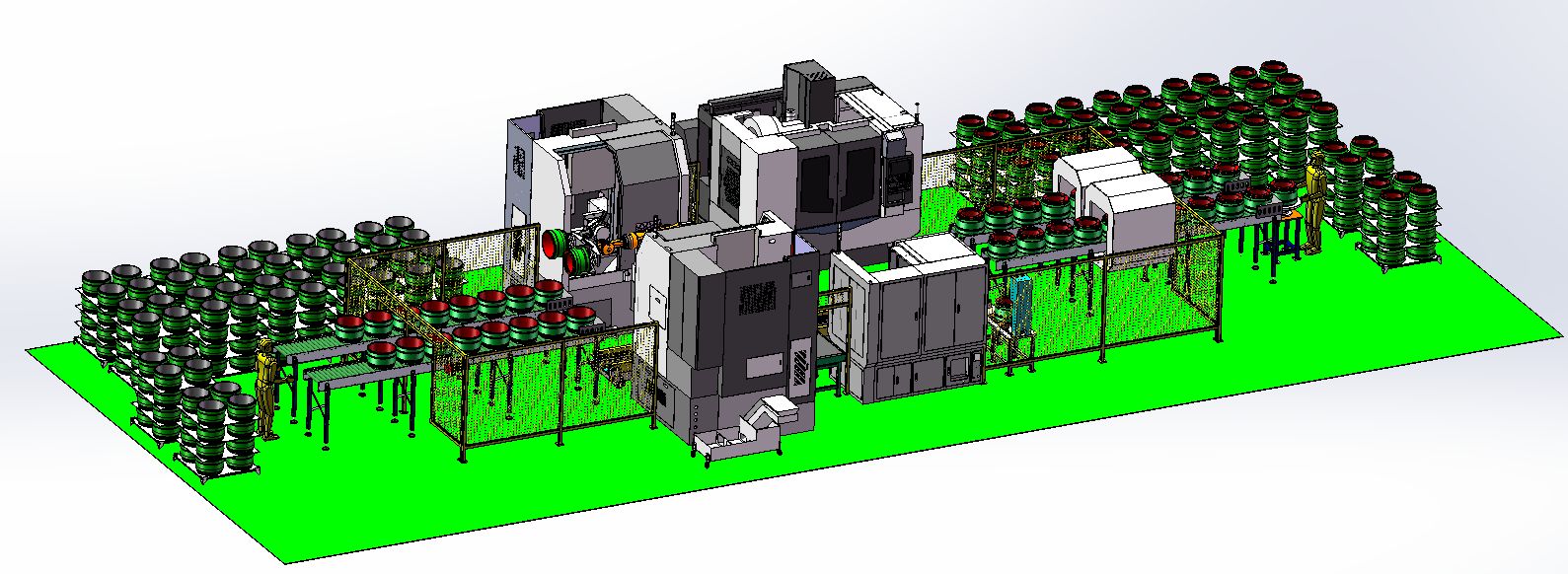

Kamangidwe ka Production Line

Chiyambi cha Production Line

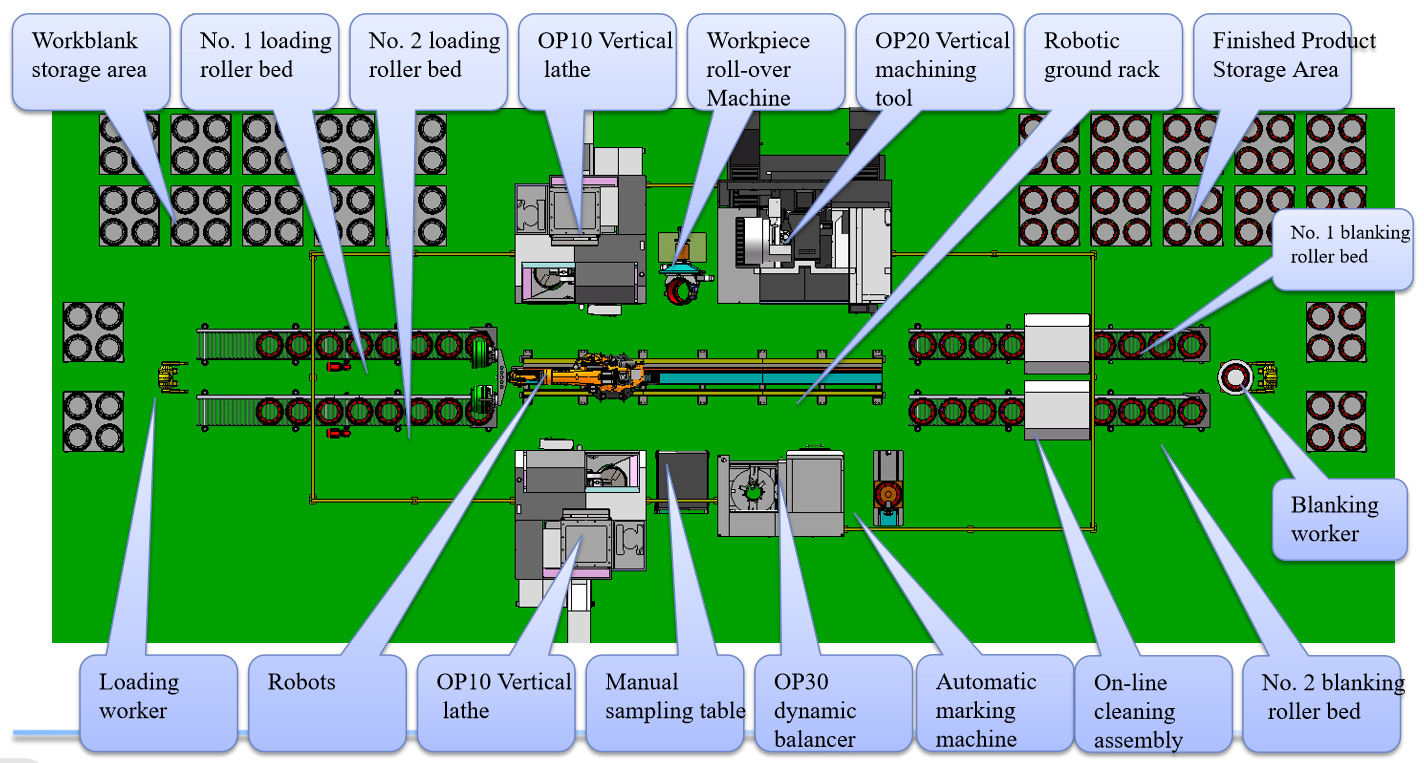

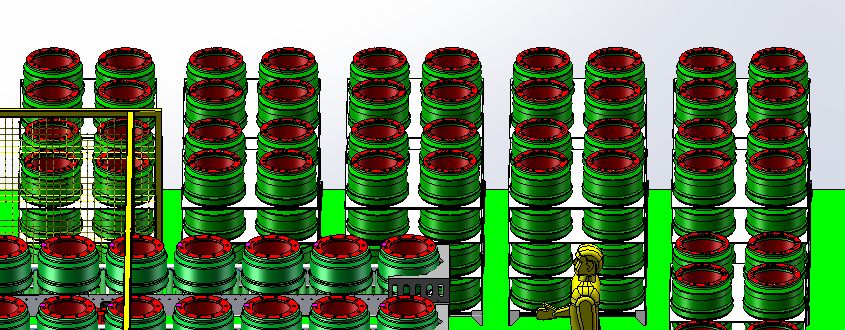

Mzerewu uli ndi 1 loading unit, 1 lathe Machining unit ndi 1 blanking unit. Maloboti amanyamula katundu pakati pa masiteshoni mkati mwa gawo lililonse. Forklifts amayika madengu kutsogolo kwa mayunitsi onyamula ndi opanda kanthu; Mzere wopanga umakwirira kudera la: 22.5m×9m

Kufotokozera kwa mzere wopanga

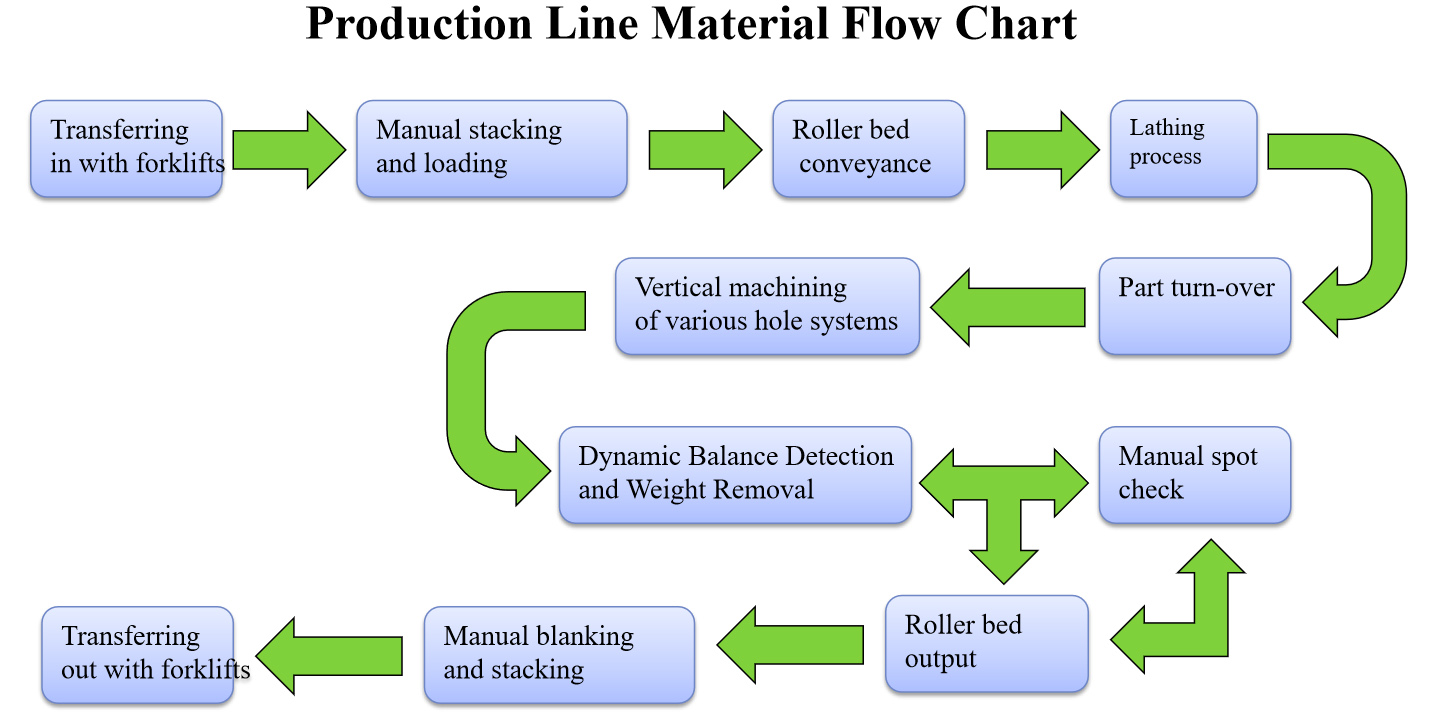

1. Zolemba za ntchito zimatumizidwa kumalo osungiramo katundu ndi ma forklift, amakwezedwa pamanja ku bedi lodzigudubuza, ndi kutumizidwa kumalo osungiramo katundu kupyolera mwa odzigudubuza. Kutsitsa ndi kutsitsa makina osakanikirana mu njira ya lathe, njira yopititsira patsogolo ndi kubowola ndi mphero zimatsirizidwa ndi maloboti. Zotsirizidwazo zimatumizidwa kumalo osabisa kanthu kudzera pa bedi lodzigudubuza, ndikutumizidwa ndi ma forklifts pambuyo pokweza pamanja ndikuyika;

2. Zowonetsera zazikulu zamagetsi zamagetsi zidzakhazikitsidwa pamizere yotumizira zinthu kuti zisinthe ndikuwonetsa zambiri zomwe zimachokera, zinthu zolakwika ndi masiku opanga chitetezo mu nthawi yeniyeni;

3. Chingwe chotumizira chidzaperekedwa ndi kuwala kochenjeza pa unit iliyonse, yomwe ingathe kuwonetsa zambiri monga zachilendo, kusowa kwa zinthu ndi zoopsa;

4. Mzere wodziwikiratu umatengera makina opangira ma unit ndi ma multi-unit wiring mode, okhala ndi masanjidwe osinthika, oyenera pazofunikira zosiyanasiyana zamakasitomala;

5. Landirani loboti yolumikizana kuti muyike ndikuyimitsa, yomwe imakhala yokhazikika, kukonza bwino komanso moyo wautali wautumiki;

6. Kufuna kochepa kwa ogwira ntchito. Zomwe anthu amafunikira tsiku lililonse pakusintha kulikonse kwa mzere wodziwikiratu ndi motere:

Forkliftman 1 ~ 2 anthu (oyang'anira kukweza, kukweza ma forklift ndi kusamutsa opanda kanthu / zinthu zomalizidwa)

Maintenance Engineer 1 munthu (oyang'anira kukonza nthawi zonse-odula mafuta ndi madzi, etc.)

7. Mzere wodziwikiratu uli ndi mphamvu zowonjezera. Monga makina osakanikirana a waya, traceability ndi ntchito zina, ndi mtengo wotsika wowonjezera;

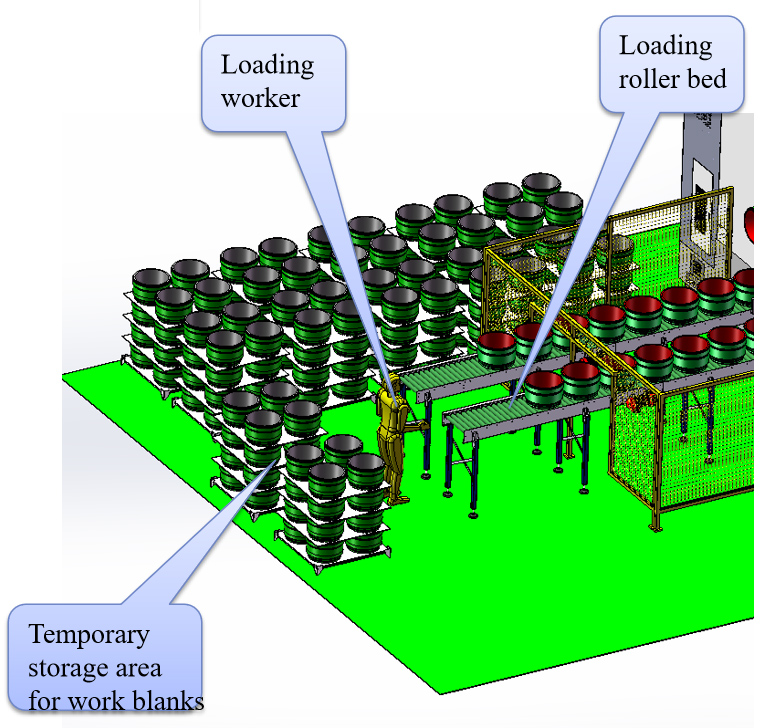

Loading unit

1. Mzere wa bedi wonyamula katundu ukhoza kusunga 12 × 16 = 192 zidutswa; 2. Tsegulani pamanja paketiyo ndikuyikweza ku bedi lodzigudubuza ndikulitumiza ku malo ojambulira ndi cholumikizira; 3. Mukatsegula stack, thireyi yopanda kanthu iyenera kumangirizidwa ndikuyikidwa pamzere wopanda kanthu wa trays opanda kanthu, ndikuyika mu zigawo za 8, ndipo thireyi yopanda kanthu idzachotsedwa pamanja ndikuyika malo osungira;1. Wodzigudubuza bedi mzere akhoza kusunga 12 × 16 = 192 zidutswa;

2. Tsegulani pamanja paketiyo ndikuyikweza ku bedi lodzigudubuza ndikulitumiza ku malo ojambulira ndi cholumikizira;

3. Pambuyo potsegula stack, thireyi yopanda kanthu iyenera kutsekedwa ndikuyikidwa pamzere wopanda kanthu wa trays opanda kanthu, ndikuyika mu zigawo za 8, ndipo thireyi yopanda kanthu idzachotsedwa pamanja ndikuyika malo osungira;

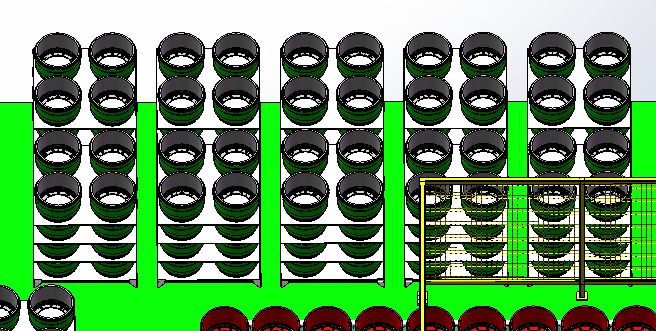

Chiyambi cha ntchito zopanda kanthu milu

1. Mulu umodzi wa zidutswa 16 ndi zigawo 4 zonse, ndi mbale zogawa pakati pa wosanjikiza uliwonse;

2. Ntchito yopanda kanthu imatha kusunga zidutswa 160;

3. Phale liyenera kukonzedwa ndi kasitomala. Chofunikira: (1) Kukhazikika bwino komanso kukhazikika (2) kukhala wokhoza kukakamizidwa ndi loboti.

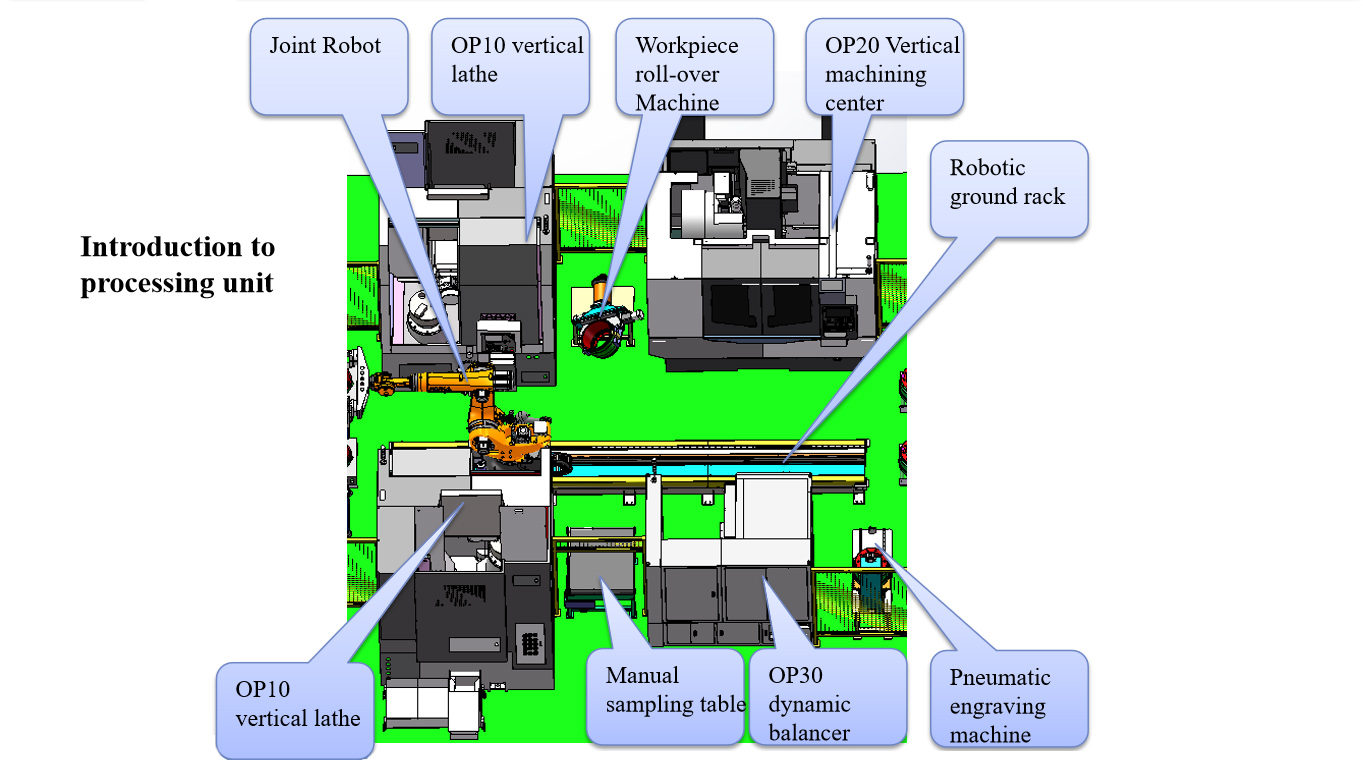

Chiyambi cha processing unit

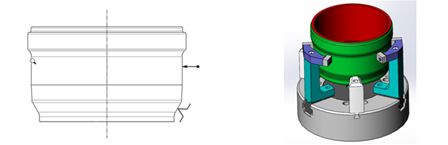

1. The lathing ndondomeko tichipeza awiri ofukula lathes, No. 1 loboti ndi loboti pansi pachithandara, amene amachita Machining wa bwalo lakunja, m'dzenje sitepe pamwamba ndi mapeto nkhope ya gawo;

2. Malo osinthira amakhala ndi makina amodzi ogudubuza, omwe amangogubuduza magawo;

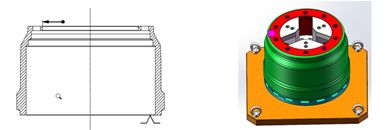

3. Kubowola ndi mphero kumakhala ndi 1 ofukula makina opangira makina ndi robot imodzi No.

4. Njira yosinthira ndikuchotsa zolemetsa imakhala ndi vertical dynamic balancer, yomwe imayang'anira kuzindikira ndikuchotsa kulemera kwa magawo;

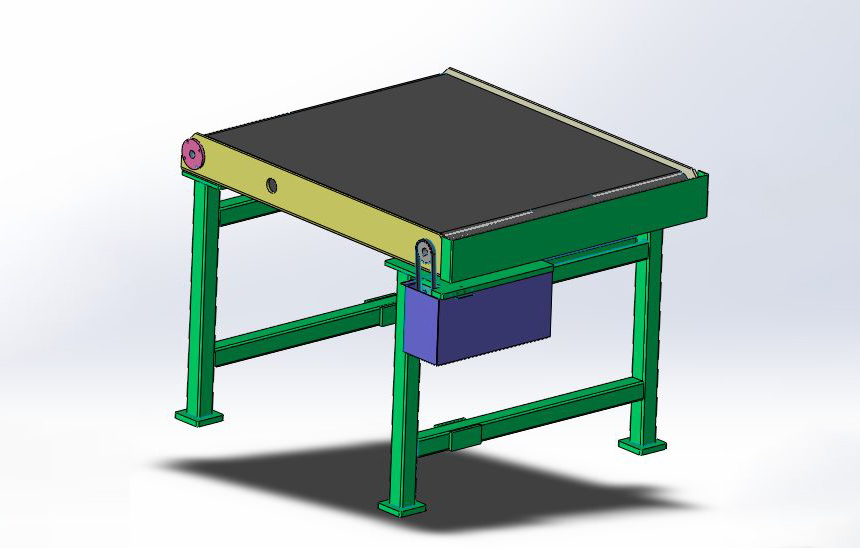

5. Malo oyang'anira malo opangira mabuku amakhala ndi conveyor lamba, omwe amayendetsa magawo omwe amafufuzidwa ndipo amagwiritsidwa ntchito ngati malo oyendera;

6. Malo ogwirira ntchito a makina osindikizira a pneumatic amagwira ntchito yojambula ndi kulemba zolemba zonse;

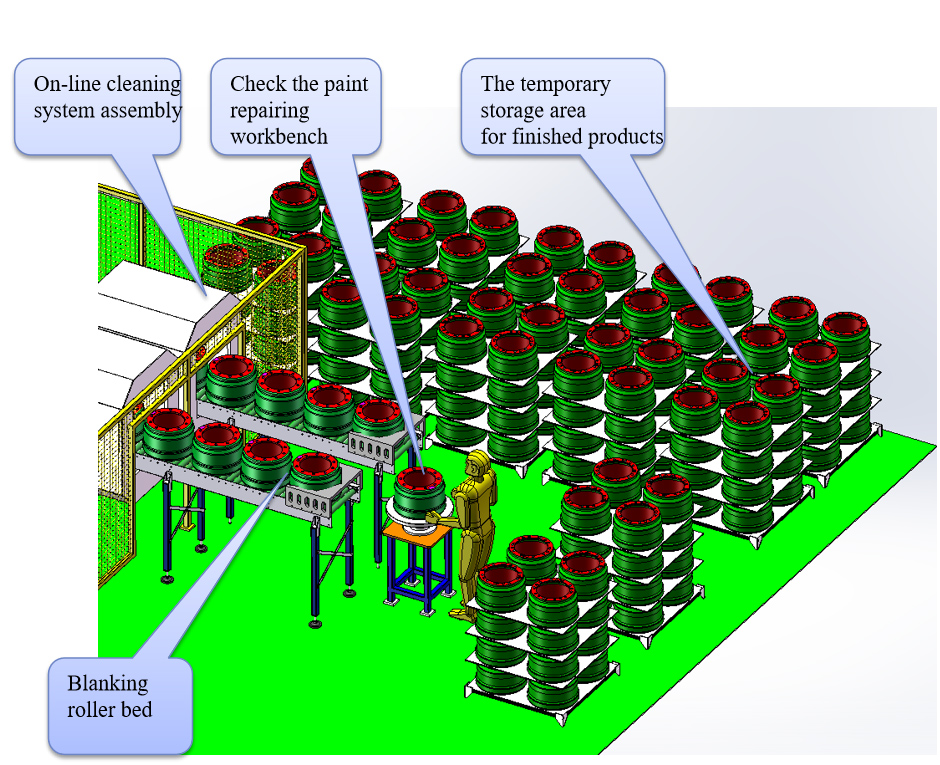

Kuyamba kwa gawo lopanda kanthu

1. Mzere wa bedi wonyamula katundu ukhoza kusunga 12 × 16 = 192 zidutswa;

2. Ma tray ndi ma partition plates pa malo onyamula katundu amatengedwa kupita kumalo opanda kanthu ndi forklifts;

3. Zinthu zomalizidwa zimatengedwa kupita ku malo opanda kanthu ndi chotengera chodzigudubuza, ndipo zimakwezedwa ndikumangika pamanja ndikusamutsidwa ndi ma forklift;

Kufotokozera za kumaliza mankhwala stacking

1. Mulu umodzi wa zidutswa 16 ndi zigawo 4 zonse, ndi mbale zogawa pakati pa wosanjikiza uliwonse;

2.192 zidutswa akhoza kusungidwa mulu wa zomalizidwa;

3. Phale liyenera kukonzedwa ndi kasitomala. Chofunikira: (1) Kukhazikika bwino komanso kukhazikika (2) kukhala wokhoza kukakamizidwa ndi loboti.

Kuyambitsa zigawo zikuluzikulu zogwirira ntchito za mzere wopanga

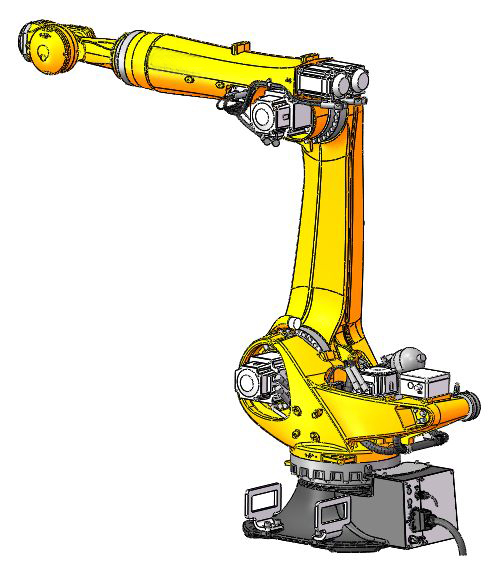

Chiyambi cha Machining ndi Dynamic Balancing Weight Removal Unit Robot

Roboti ya Chenxuan: SDCX-RB08A3-1700

| Deta yoyambira | |

| Mtundu | SDCX-RB08A3-1700 |

| Chiwerengero cha nkhwangwa | 6 |

| Kuphimba kwakukulu | 3100 mm |

| Pose kubwereza (ISO 9283) | ± 0.05mm |

| Kulemera | 1134kg |

| Gulu la chitetezo cha robot | Mulingo wachitetezo, IP65 / IP67pamzere wrist(IEC 60529) |

| Pokwera malo | Denga, ngodya yovomerezeka ya kupendekera ≤ 0º |

| Kumaliza pamwamba, utoto | Chimango choyambira: chakuda (RAL 9005) |

| Kutentha kozungulira | |

| Ntchito | 283 K mpaka 328 K (0 °C mpaka +55 °C) |

| Kusungirako ndi mayendedwe | 233 K mpaka 333 K (-40 °C mpaka +60 °C) |

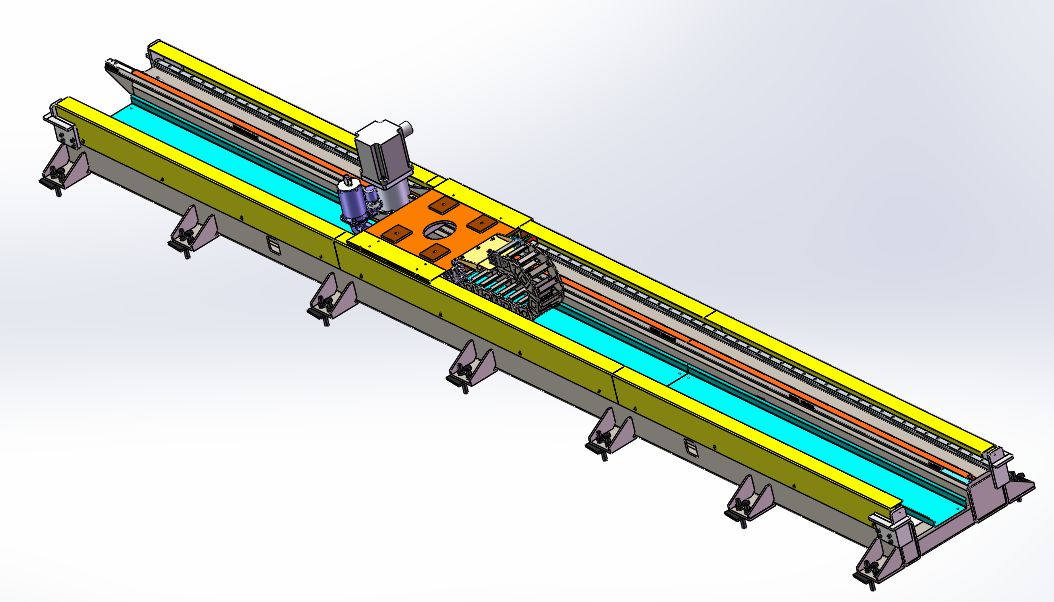

Kuyambitsa kwa Robot Travel Axis

Kapangidwe kake kamakhala ndi loboti yolumikizana, servo motor drive ndi pinion ndi rack drive, kotero kuti loboti imatha kupanga rectilinear kuyenda uku ndi uku. Imazindikira ntchito ya loboti imodzi yomwe imagwiritsa ntchito zida zingapo zamakina ndi zogwirira ntchito pamasiteshoni angapo ndipo imatha kukulitsa maloboti olumikizana;

Njira yoyendayenda imagwiritsa ntchito maziko omwe amawotcherera ndi mapaipi achitsulo ndipo amayendetsedwa ndi servo motor, pinion ndi rack drive, kuti awonjezere kuphimba kwa loboti yolumikizana ndikuwongolera bwino momwe loboti imagwiritsidwira ntchito;

Njira yoyendayenda imayikidwa pansi;

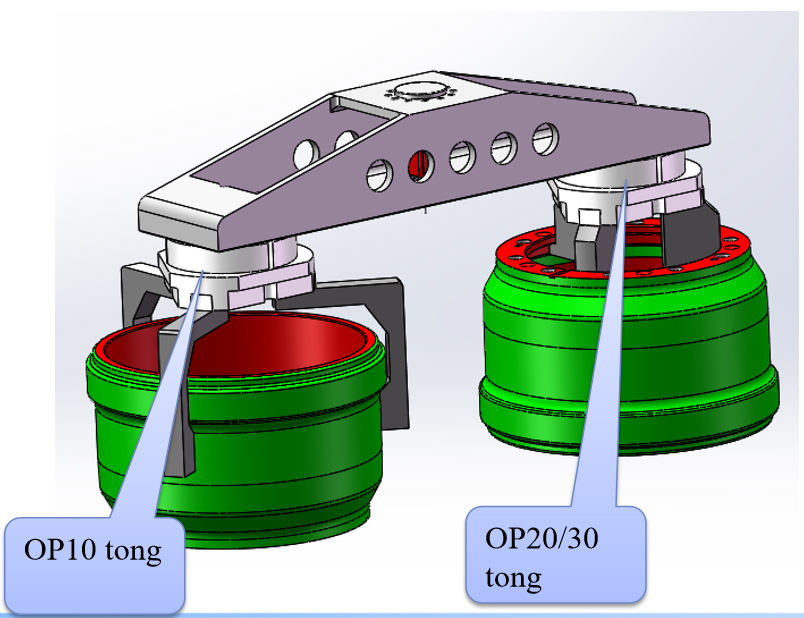

Chiyambi cha ziwalo za maloboti otsegula ndi opanda kanthu

Kufotokozera:

1. Monga momwe zimakhalira ndi gawo ili, timatengera mawonekedwe akunja a zikhadabo zitatu;

2. Makinawa amakhala ndi sensa yodziwira malo ndi sensor yokakamiza kuti azindikire ngati mawonekedwe a clamping ndi kukakamizidwa kwa magawo ndizabwinobwino;

3. Makinawa ali ndi makina osindikizira, ndipo chogwiritsira ntchito sichidzagwa mu nthawi yochepa ngati mphamvu ikulephera ndi kudulidwa kwa mpweya wa dera lalikulu la mpweya;

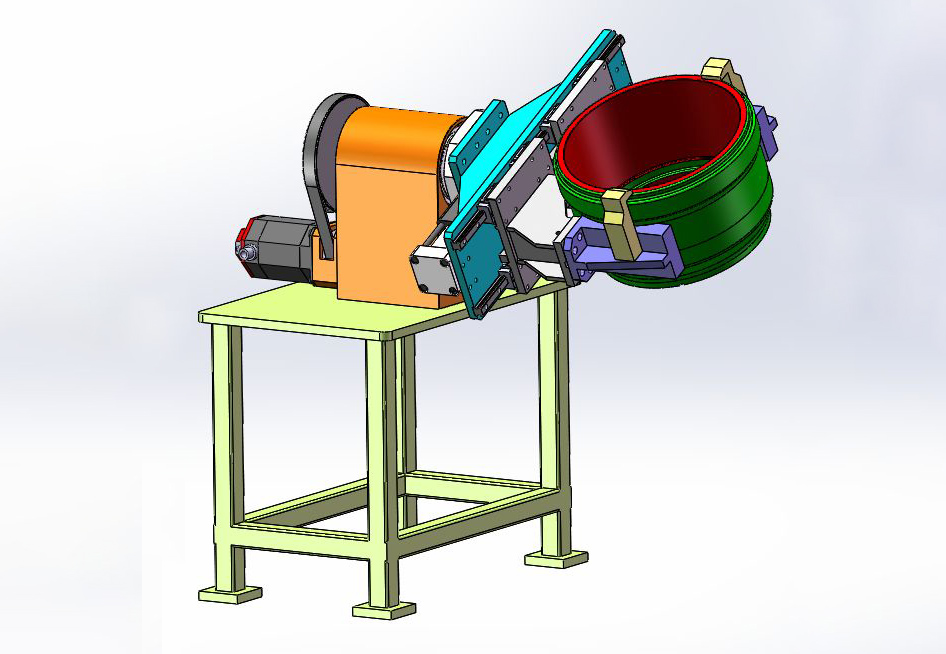

Kuyambitsa Makina Odzigudubuza Odzipangira okha

Kufotokozera:

Makinawa amapangidwa ndi chimango chokhazikika, msonkhano woyambira wothandizira ndi msonkhano wa pneumatic tong. Ili ndi ntchito yotsutsa-yotayirira komanso yotsutsa-kugwetsa pambuyo pa kudulidwa kwa mpweya, ndipo imatha kuzindikira 180 ° roll over of workpieces;

Chidziwitso cha benchi yoyang'anira mawanga

Kufotokozera:

1. Khazikitsani mafupipafupi a masampu amanja amanja pamagawo osiyanasiyana opangira, omwe amatha kuyang'anira bwino ntchito yoyezera pa intaneti;

2. Malangizo Ogwiritsira Ntchito: The manipulator adzayika workpiece pa malo oikidwa pamalo cheke benchi malinga ndi pafupipafupi anapereka pamanja, ndi mwamsanga ndi kuwala kofiira. Woyang'anira adzasindikiza batani kuti anyamule chogwirira ntchito kumalo otetezeka kunja kwa chitetezo, atenge chogwirira ntchito kuti ayese ndikuchibwezera ku bedi lodzigudubuza pambuyo poyeza;

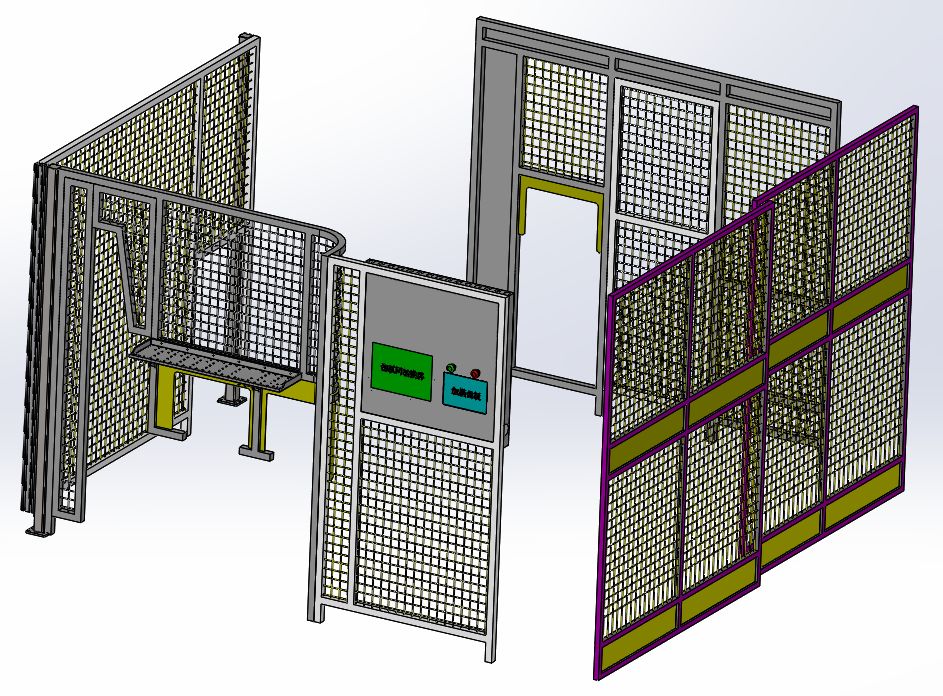

Zigawo zoteteza

Zimapangidwa ndi mbiri ya aluminiyamu yopepuka (40 × 40) + mauna (50 × 50), ndipo chotchinga chokhudza ndi batani loyimitsa mwadzidzidzi zitha kuphatikizidwa pazigawo zoteteza, kuphatikiza chitetezo ndi kukongola.

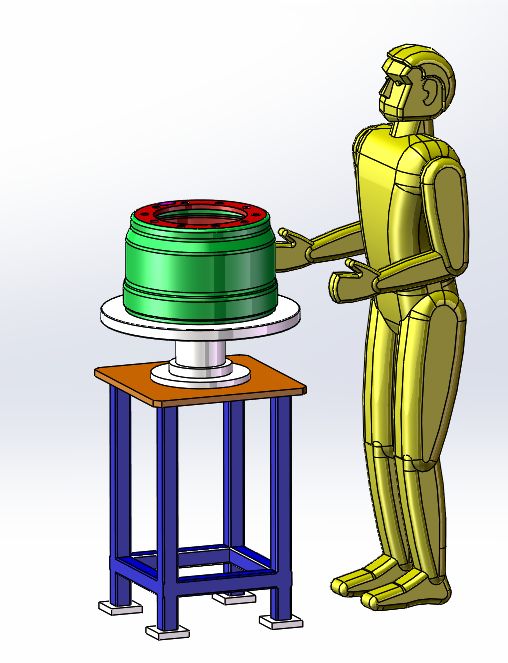

Chiyambi cha Inspection Station pokonza utoto

Kufotokozera:

Makinawa amapangidwa ndi chimango chokhazikika komanso chosinthira. Ogwira ntchito amakweza zinthu zomwe zamalizidwa ku turntable, tembenuzani chotchinga, fufuzani ngati pali tokhala, zokopa ndi zochitika zina, ndikukonza panthawi yake zowonongeka ndi utoto;