Chidule cha Ntchito

1. Pulogalamu Yopanga

600 seti / tsiku (117/118 oyenda pansi)

2. Zofunikira pakukonza mzere:

1) NC Machining Center oyenera mzere kupanga basi;

2) hydraulic frock clamp;

3) Makina otsegula ndi osatsegula ndi chipangizo chotumizira;

4) Ukadaulo wonse waumisiri ndi nthawi yozungulira;

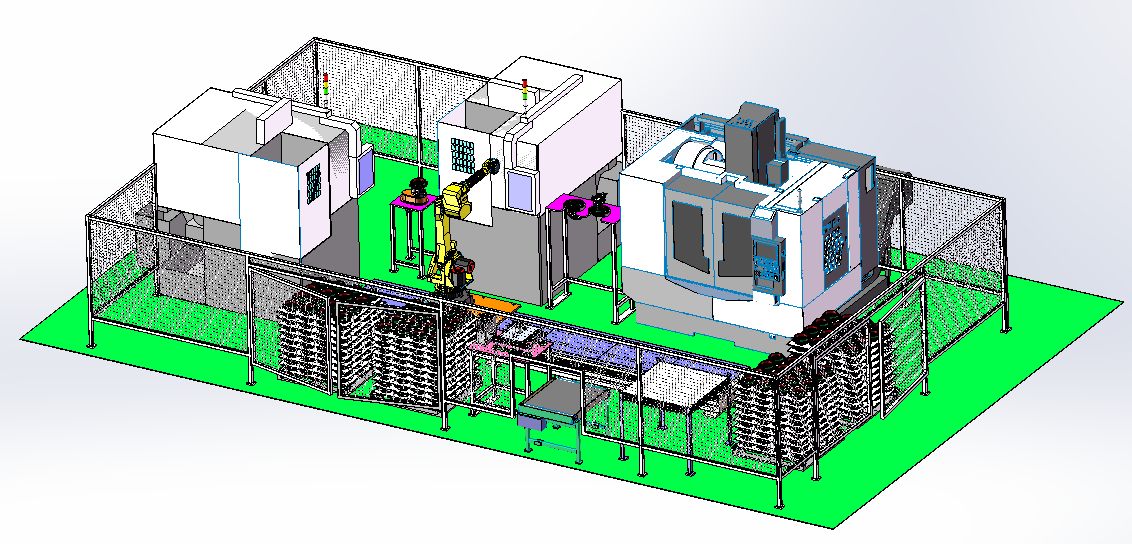

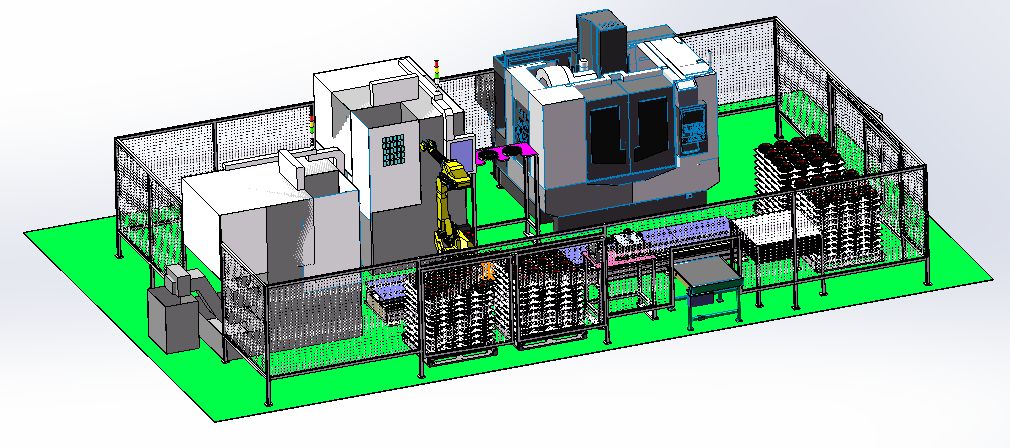

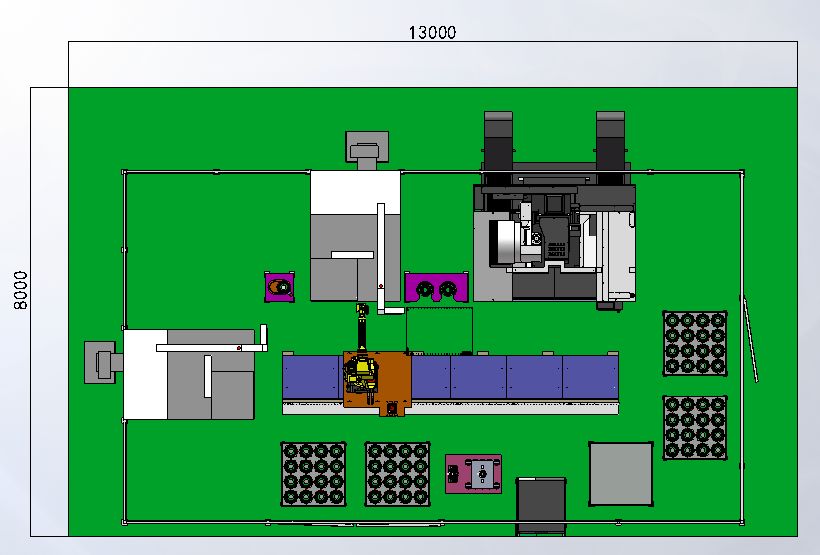

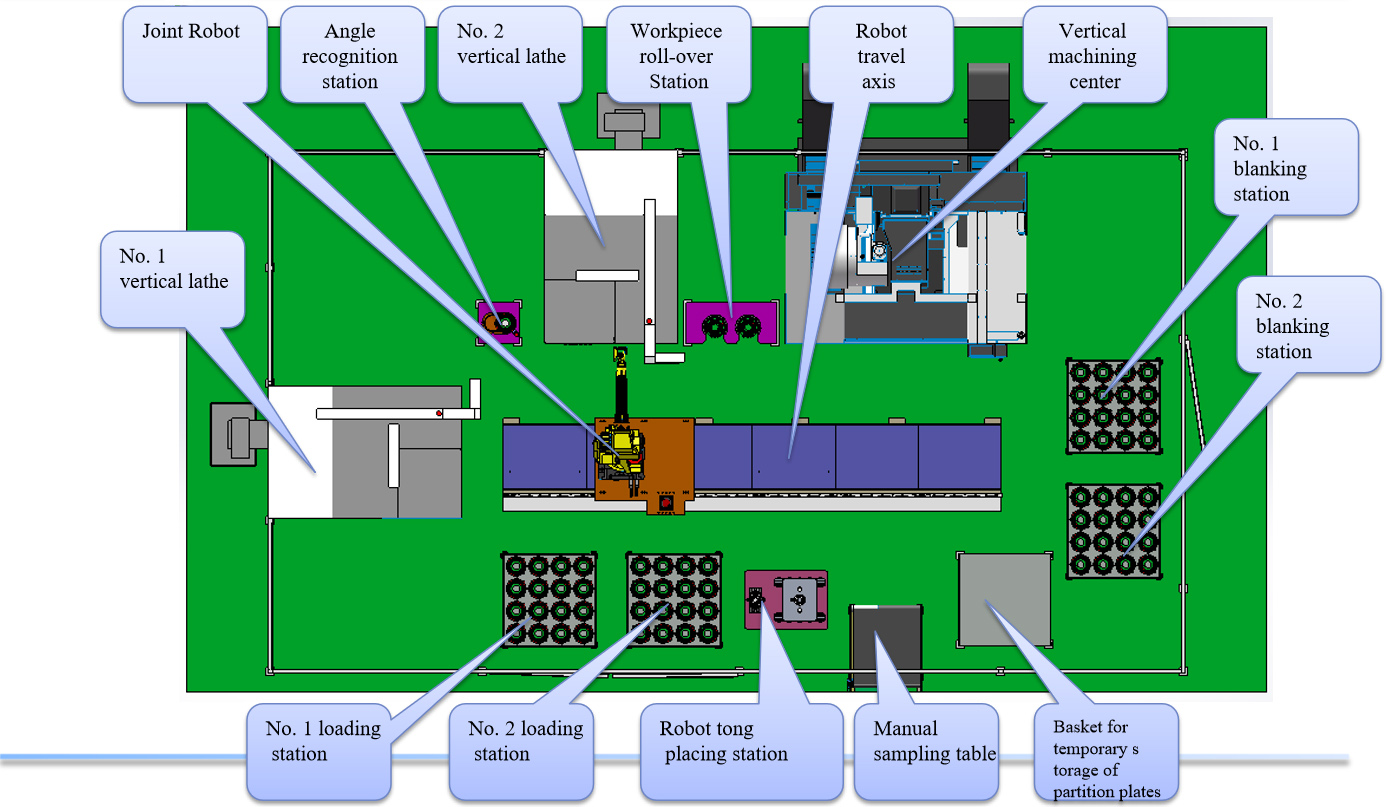

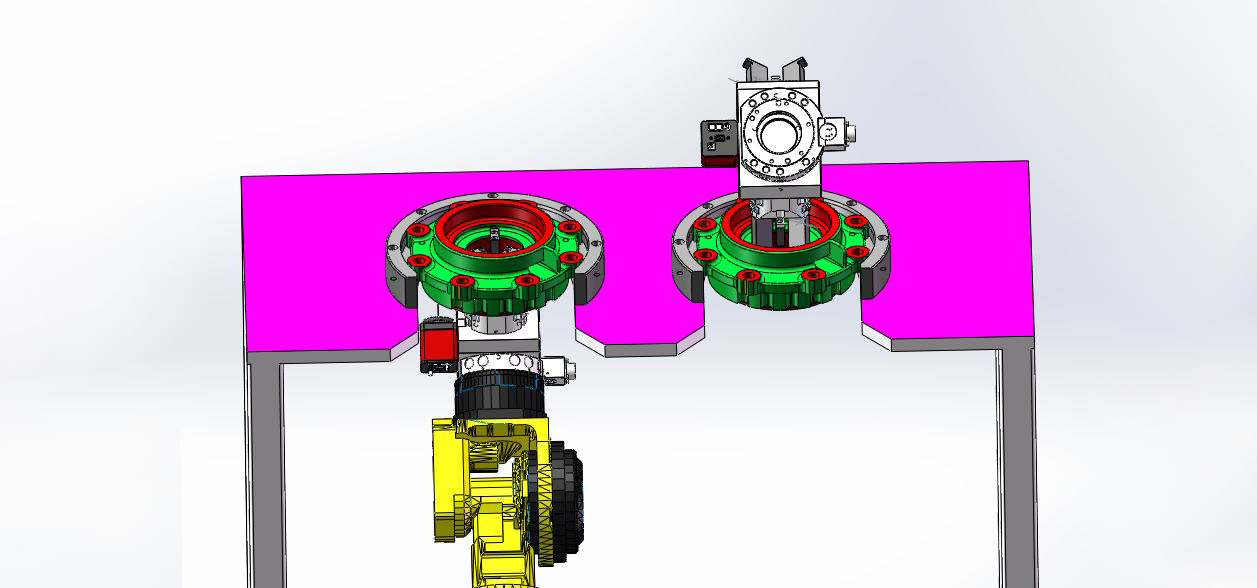

Mapangidwe a Mizere Yopanga

Mapangidwe a Mizere Yopanga

Chiyambi cha Zochita za Robot:

1. Ikani pamanja mabasiketi opangidwa movutikira ndikuyika patebulo lotsitsa (Kutsitsa matebulo No. 1 ndi No. 2) ndikudina batani kuti mutsimikizire;

2. Robot imasunthira ku tray ya No. 1 yotsegula tebulo, imatsegula dongosolo la masomphenya, imagwira ndi kusuntha Gawo A ndi B motsatira kumalo owonera angular kuti adikire malangizo otsegula;

3. Malangizo otsegula amatumizidwa ndi siteshoni yozindikiritsa angular. Roboti imayika chidutswa cha 1 pamalo oyikapo pompopompo. Tembenuzani turntable ndikuyambitsa dongosolo lozindikiritsa ang'ono, dziwani malo aang'ono, kuyimitsa chowongolera ndikumaliza kuzindikira kwa angular kwa chidutswa cha 1;

4. Chidziwitso cha angular chimatumiza lamulo lopanda kanthu, ndipo robot imatenga chidutswa cha 1 ndikuyika chidutswa cha 2 kuti chizindikirike. The turntable imazungulira ndipo dongosolo lozindikiritsa angular limayamba kuti mudziwe malo aang'ono. The turntable amaima ndi kuzindikira angular chidutswa No.

5. Loboti imalandira lamulo lopanda kanthu la 1 vertical lathe, imasunthira kumalo otsegula ndi opanda kanthu a No. Ntchitoyo ikamalizidwa, makina amtundu umodzi wa lathe ofukula akuyamba;

6. Roboti imatenga zinthu zomalizidwa ndi No. 1 vertical lathe ndikuziyika pa No.

7. The loboti amalandira blanking lamulo la No. 2 ofukula lathe, amapita potsegula ndi blanking udindo wa No. 2 ofukula lathe kwa blanking zinthu ndi Kutsegula., ndiyeno kanthu anamaliza, ndi single-chidutswa processing mkombero wa lathe ofukula akuyamba;

8. Roboti imatenga zinthu zomalizidwa ndi No. 2 vertical lathe ndikuziyika pa No.

9. Loboti imadikirira lamulo losatchulika kuchokera ku makina osunthika;

10. Makina osunthika amatumiza lamulo lopanda kanthu, ndipo loboti imasunthira kumalo osungira ndi osatsegula a makina osunthika, imagwira ndi kusuntha zida zogwirira ntchito za No. 1 ndi No. The loboti kusuntha kwa mpukutu tebulo kumvetsa ndi kutumiza No. 1 ndi No. 2 zidutswa kwa ofukula Machining Mumakonda ndi malo blanking motero, ndi malo No. 1 ndi No. 2 workpieces mu malo udindo wa No. 1 ndi No. Loboti imachoka pamtunda wachitetezo cha makina osunthika ndikuyambitsa njira imodzi yopangira;

11. Robot imasunthira ku Nambala 1 yonyamula tray ndikukonzekera kuyambitsa pulogalamu yachiwiri yozungulira;

Kufotokozera:

1. Loboti imatenga zidutswa 16 (wosanjikiza umodzi) pa tray yotsitsa. Loboti ilowa m'malo mwa kapu yoyamwa ndikuyika mbale yogawa mudengu losungirako kwakanthawi;

2. Loboti imanyamula zidutswa 16 (m'modzi wosanjikiza) pa tray yopanda kanthu. Loboti ilowe m'malo mwa kapu yoyamwa kamodzi, ndikuyika mbale yogawa pagawo la magawo omwe ali mudengu losungirako kwakanthawi;

3. Malingana ndi maulendo oyendera, onetsetsani kuti loboti imayika gawo pa tebulo lachitsanzo;

| 1 | Nthawi yozungulira makina | ||||||||||||||

| 2 | Makasitomala | Zida zogwirira ntchito | QT450-10-GB/T1348 | Chitsanzo cha chida cha makina | Archive No. | ||||||||||

| 3 | Dzina lazogulitsa | 117 Kunyamula mpando | Chojambula No. | DZ90129320117 | Tsiku lokonzekera | 2020.01.04 | Okonza | ||||||||

| 4 | Njira sitepe | Mpeni No. | makina okhutira | Dzina lachida | Kudula Diameter | Kudula liwiro | Liwiro lozungulira | Chakudya pa kusintha | Kudyetsa ndi chida makina | Chiwerengero cha cuttings | Njira iliyonse | Machining nthawi | Idle Time | Nthawi yozungulira ma axis anayi | Chida chosintha nthawi |

| 5 | Ayi. | Ayi. | Desoriptions | Zida | D mm | n | R pm | mm / Rev | mm/Mphindi | Nthawi | mm | Sec | Sec | Sec | |

| 6 |  | ||||||||||||||

| 7 | 1 | T01 | Mphero ogwiritsa dzenje pamwamba | Diameter ya 40-face milling cutter | 40.00 | 180 | 1433 | 1.00 | 1433 | 8 | 40.0 | 13.40 | 8 | 4 | |

| 8 | Boolani mabowo okwera a DIA 17 | DIA 17 WOGWIRITSA NTCHITO | 17.00 | 100 | 1873 | 0.25 | 468 | 8 | 32.0 | 32.80 | 8 | 4 | |||

| 9 | T03 | DIA 17 dzenje kumbuyo chamfering | Reverse chamfering cutter | 16.00 | 150 | 2986 | 0.30 | 896 | 8 | 30.0 | 16.08 | 16 | 4 | ||

| 10 | Kufotokozera: | Nthawi yodula: | 62 | Chachiwiri | Nthawi yokhomerera ndi fixture komanso kutsitsa ndi kusalemba zinthu: | 30.00 | Chachiwiri | ||||||||

| 11 | Nthawi Yothandizira: | 44 | Chachiwiri | Maola onse opangira makina: | 136.27 | Chachiwiri | |||||||||

| 1 | Nthawi yozungulira makina | |||||||||||||||||

| 2 | Makasitomala | Zida zogwirira ntchito | QT450-10-GB/T1348 | Chitsanzo cha chida cha makina | Archive No. | |||||||||||||

| 3 | Dzina lazogulitsa | 118 Kunyamula mpando | Chojambula No. | DZ90129320118 | Tsiku lokonzekera | 2020.01.04 | Okonza | |||||||||||

| 4 | Njira sitepe | Mpeni No. | makina okhutira | Dzina lachida | Kudula Diameter | Kudula liwiro | Liwiro lozungulira | Chakudya pa kusintha | kudyetsa ndi chida makina | Chiwerengero cha cuttings | Njira iliyonse | Machining nthawi | Idle Time | Nthawi yozungulira ma axis anayi | Chida chosintha nthawi | |||

| 5 | Ayi. | Ayi. | Desoriptions | Zida | D mm | n | R pm | mm / Rev | mm/Mphindi | Nthawi | mm | Sec | Sec | Sec | ||||

| 6 |

| |||||||||||||||||

| 7 | 1 | T01 | Mphero ogwiritsa dzenje pamwamba | Diameter ya 40-face milling cutter | 40.00 | 180 | 1433 | 1.00 | 1433 | 8 | 40.0 | 13.40 | 8 | 4 | ||||

| 8 | T02 | Boolani mabowo okwera a DIA 17 | DIA 17 WOGWIRITSA NTCHITO | 17.00 | 100 | 1873 | 0.25 | 468 | 8 | 32.0 | 32.80 | 8 | 4 | |||||

| 9 | T03 | DIA 17 dzenje kumbuyo chamfering | Reverse chamfering cutter | 16.00 | 150 | 2986 | 0.30 | 896 | 8 | 30.0 | 16.08 | 16 | 4 | |||||

| 10 | Kufotokozera: | Nthawi yodula: | 62 | Chachiwiri | Nthawi yokhomerera ndi fixture komanso kutsitsa ndi kusalemba zinthu: | 30.00 | Chachiwiri | |||||||||||

| 11 | Nthawi Yothandizira: | 44 | Chachiwiri | Maola onse opangira makina: | 136.27 | Chachiwiri | ||||||||||||

| 12 | ||||||||||||||||||

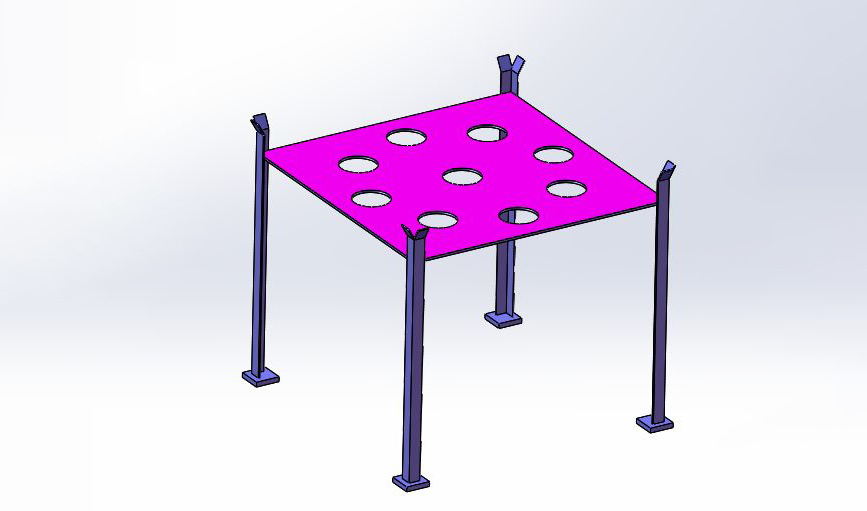

Malo ofikira pamzere wopanga

Chidziwitso cha zigawo zikuluzikulu zogwira ntchito za mzere wopanga

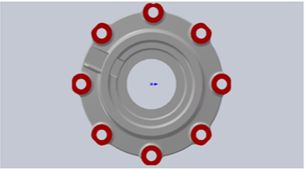

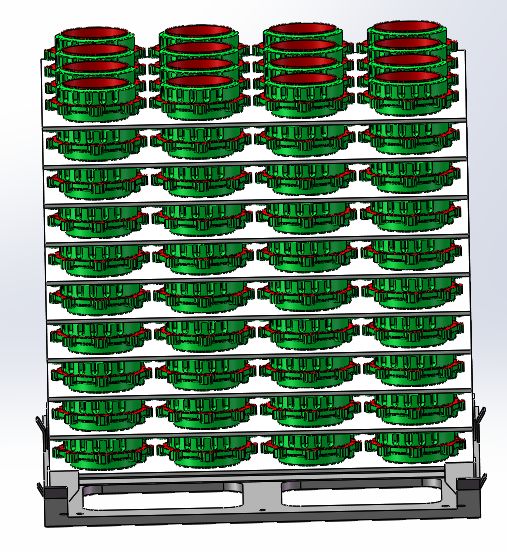

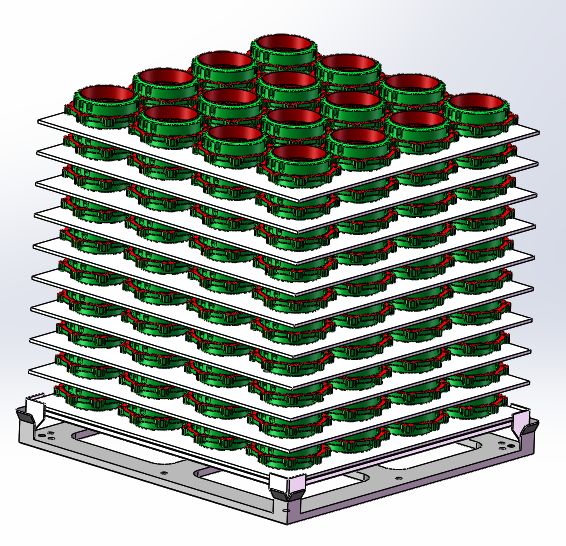

Chidziwitso cha pulogalamu yotsitsa ndi yopanda kanthu

Zida zosungiramo zida zopangira zokha mu chiwembu ichi ndi: The thireyi yodzaza (kuchuluka kwa zidutswa zomwe zimanyamulidwa pa thireyi iliyonse zidzakambidwa ndi kasitomala), ndi malo a workpiece mu tray adzatsimikiziridwa pambuyo popereka zojambula za 3D za workpiece zopanda kanthu kapena chinthu chenichenicho.

1. Ogwira ntchito amanyamula zida zomwe zakonzedwa bwino pa thireyi (monga momwe zikuwonekera pachithunzichi) ndikuzikweza pamalo omwe asankhidwa;

2. Mukasintha thireyi ya forklift, dinani pamanja batani kuti mutsimikizire;

3. Loboti imagwira ntchito kuti igwire ntchito yokweza;

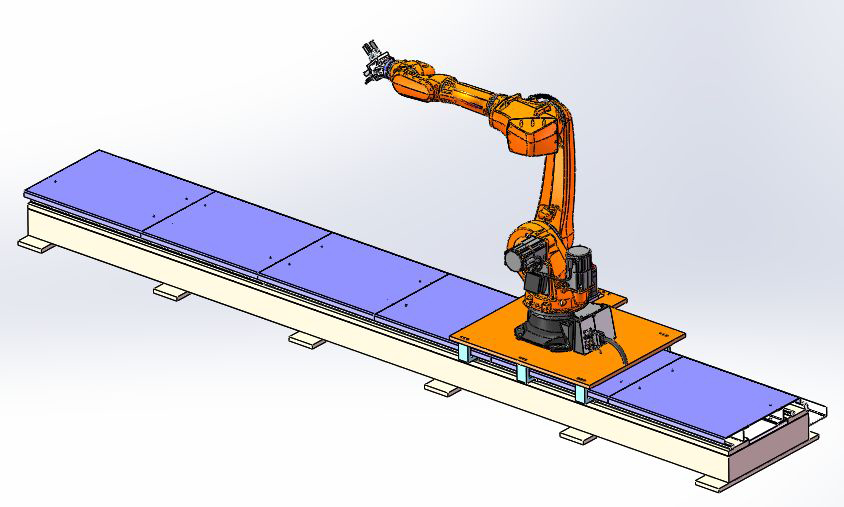

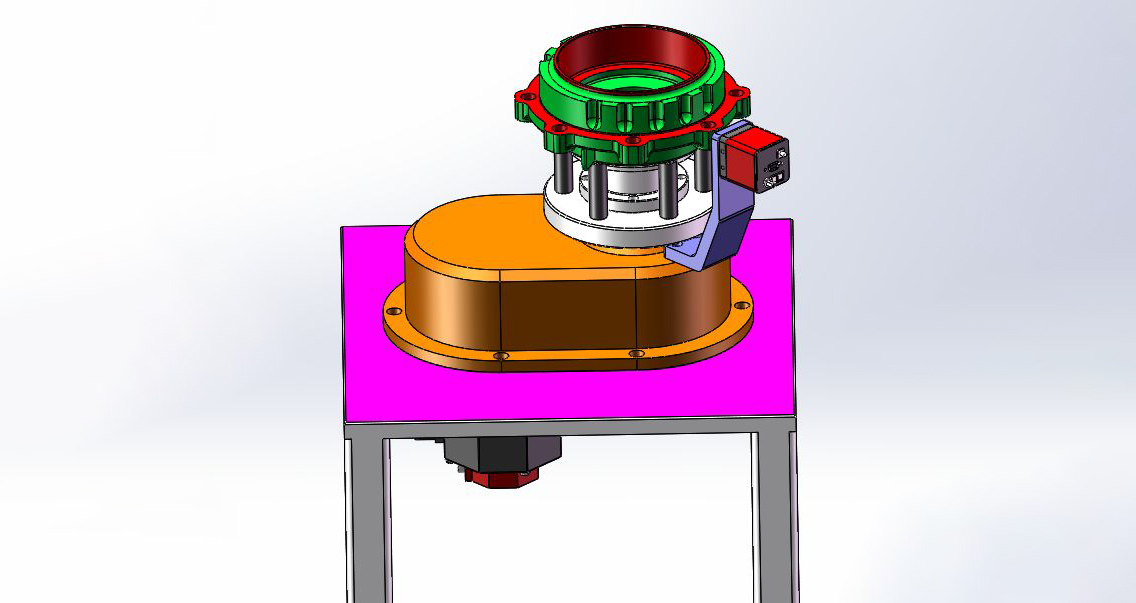

Kuyambitsa kwa Robot Travel Axis

Kapangidwe kake kamakhala ndi loboti yolumikizana, servo motor drive ndi pinion ndi rack drive, kotero kuti loboti imatha kupanga rectilinear kuyenda uku ndi uku. Imazindikira ntchito ya loboti imodzi yomwe imagwiritsa ntchito zida zingapo zamakina ndi zogwirira ntchito pamasiteshoni angapo ndipo imatha kukulitsa maloboti olumikizana;

Njira yoyendayenda imagwiritsa ntchito maziko omwe amawotcherera ndi mapaipi achitsulo ndipo amayendetsedwa ndi servo motor, pinion ndi rack drive, kuti awonjezere kuphimba kwa loboti yolumikizana ndikuwongolera bwino momwe loboti imagwiritsidwira ntchito; Njira yoyendayenda imayikidwa pansi;

Roboti ya Chenxuan:SDCX-RB500

| Deta yoyambira | |

| Mtundu | Chithunzi cha SDCX-RB500 |

| Chiwerengero cha nkhwangwa | 6 |

| Kuphimba kwakukulu | 2101 mm |

| Pose kubwereza (ISO 9283) | ± 0.05mm |

| Kulemera | 553kg pa |

| Gulu la chitetezo cha robot | Mulingo wachitetezo, IP65 / IP67pamzere wrist(IEC 60529) |

| Pokwera malo | Denga, ngodya yovomerezeka ya kupendekera ≤ 0º |

| Kumaliza pamwamba, utoto | Chimango choyambira: chakuda (RAL 9005) |

| Kutentha kozungulira | |

| Ntchito | 283 K mpaka 328 K (0 °C mpaka +55 °C) |

| Kusungirako ndi mayendedwe | 233 K mpaka 333 K (-40 °C mpaka +60 °C) |

Ndi maulendo osiyanasiyana oyendayenda kumbuyo ndi pansi pa robot, pokhala chitsanzo chokhoza kukhazikitsidwa ndi kukweza denga. Chifukwa m'lifupi mwake lobotiyo imachepetsedwa mpaka malire, ndizotheka kuyikidwa pafupi ndi loboti yoyandikana nayo, chotchingira, kapena chogwirira ntchito. Kusuntha kothamanga kwambiri kuchokera pamalo oyimilira kupita kumalo ogwirira ntchito komanso kuyika mwachangu panthawi yakuyenda mtunda waufupi.

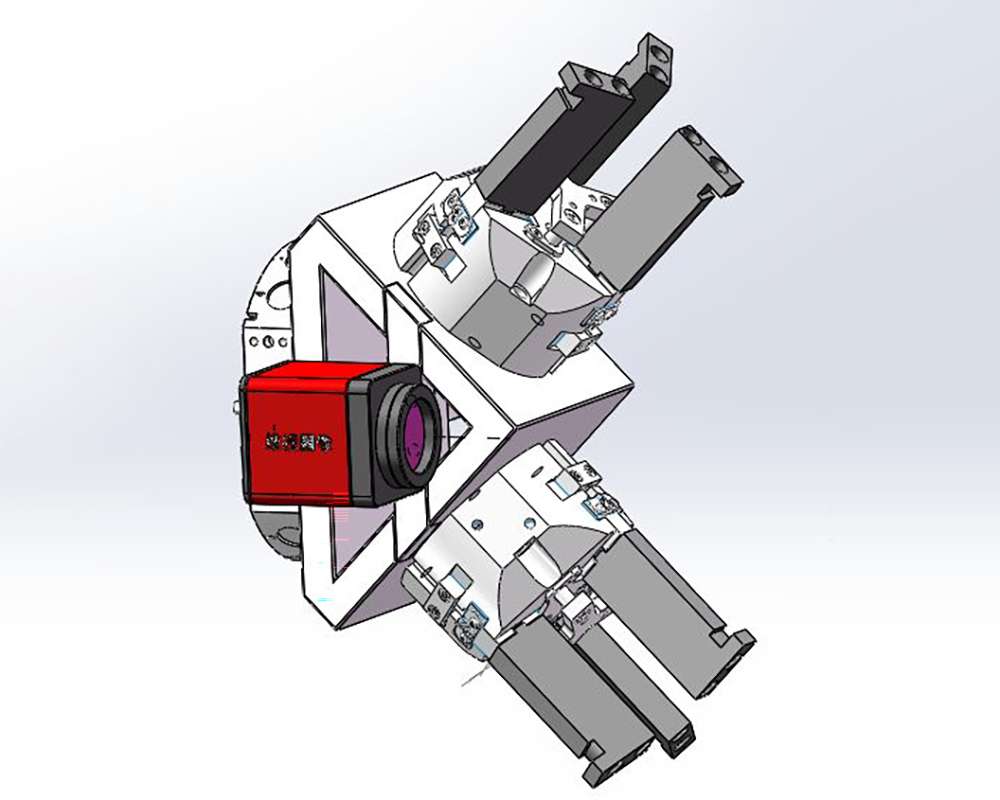

Loboti yanzeru yotsegula ndi makina osatsegula

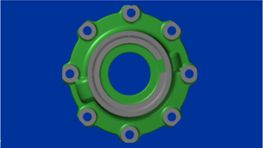

Roboti yogawa mbale tong makina

Kufotokozera:

1. Poganizira mbali za gawoli, timagwiritsa ntchito njira yothandizira kunja kwa zikhadabo zitatu kuti tinyamule ndi kuyika zinthu zopanda kanthu, zomwe zimatha kuzindikira kutembenuka mwachangu kwa magawo mu chida cha makina;

2. Makinawa amakhala ndi sensa yodziwira malo ndi sensor yokakamiza kuti azindikire ngati mawonekedwe a clamping ndi kukakamizidwa kwa magawo ndizabwinobwino;

3. Makinawa ali ndi makina osindikizira, ndipo chogwiritsira ntchito sichidzagwa mu nthawi yochepa ngati mphamvu ikulephera ndi kudulidwa kwa mpweya wa dera lalikulu la mpweya;

4. Chida chosinthira manja chimatengedwa. Kusintha makina a tong kumatha kumaliza mwachangu kukakamiza kwazinthu zosiyanasiyana.

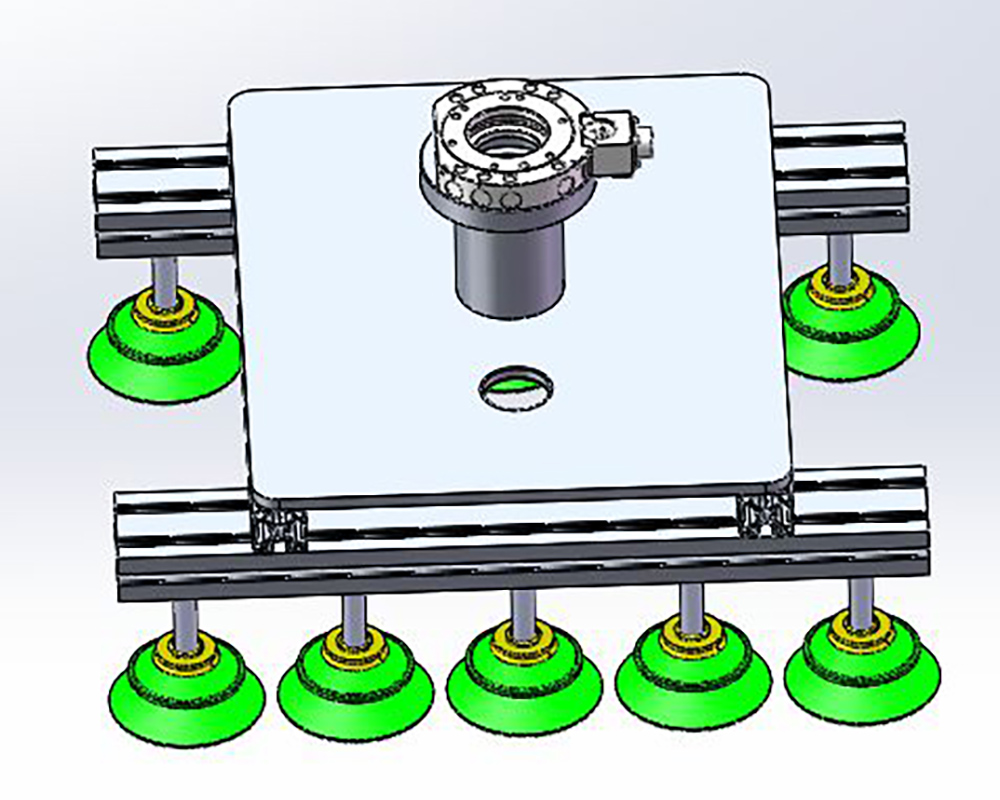

Kuyambitsa kwa Tong Changing Chipangizo

Chipangizo chosinthira ma tong cholondola chimagwiritsidwa ntchito kusintha masinthidwe amaloboti, malekezero a zida, ndi ma actuator ena. Chepetsani nthawi yopanga zopanda pake ndikuwonjezera kusinthasintha kwa roboti, zowonetsedwa ngati:

1. Tsegulani ndi kumangitsa kuthamanga kwa mpweya;

2. Ma module amphamvu osiyanasiyana, amadzimadzi ndi gasi angagwiritsidwe ntchito;

3. Standard kasinthidwe akhoza mwamsanga kugwirizana ndi mpweya gwero;

4. Mabungwe apadera a inshuwaransi angalepheretse ngozi yodula mwangozi gasi;

5. Palibe kasupe anachita mphamvu; 6. Yogwira kumunda wodzipangira;

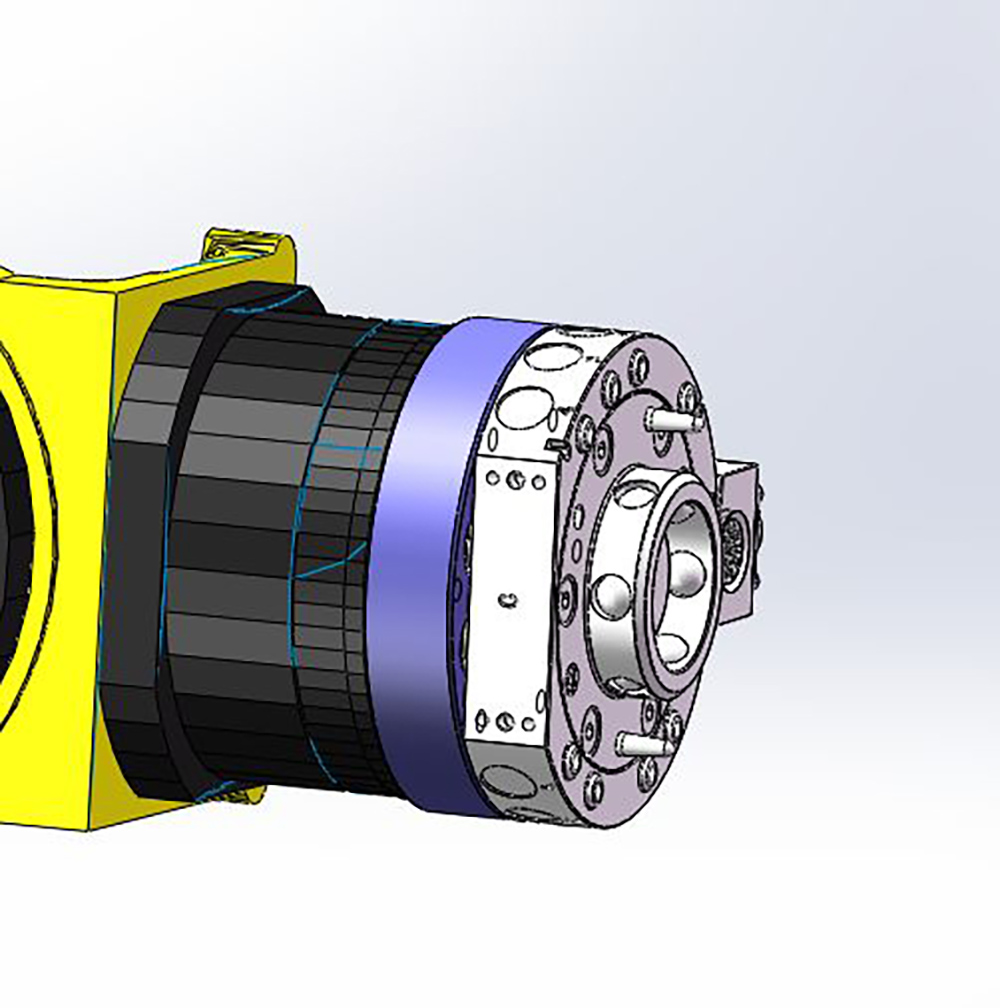

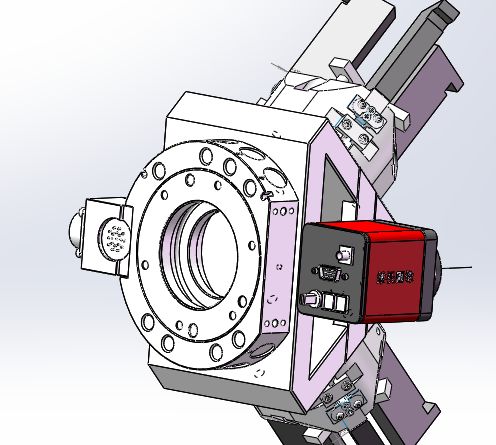

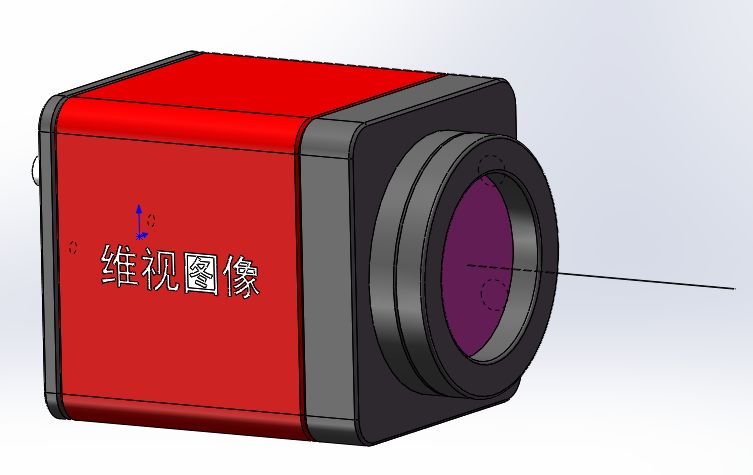

Chiyambi cha Vision System-Industrial Camera

1. Kamera imagwiritsa ntchito tchipisi tapamwamba kwambiri za CCD ndi CMDS, zomwe zimakhala ndi chiŵerengero chapamwamba, kukhudzika kwakukulu, chiwerengero chapamwamba cha chizindikiro-ndi-frequency, kusinthasintha kwakukulu, khalidwe labwino kwambiri lojambula komanso luso lobwezeretsa mtundu woyamba;

2. Kamera yamtundu wa m'dera ili ndi njira ziwiri zotumizira deta: mawonekedwe a GIGabit Ethernet (GigE) ndi mawonekedwe a USB3.0;

3. Kamera ili ndi mawonekedwe osakanikirana, mawonekedwe ang'onoang'ono, opepuka komanso oikidwa. Kuthamanga kwakukulu, mphamvu zotsutsana ndi kusokoneza, kutulutsa kokhazikika kwa chithunzi chapamwamba; Imagwiritsidwa ntchito powerenga ma code, kuzindikira zolakwika, DCR ndi kuzindikira mawonekedwe; Kamera yamtundu ili ndi mphamvu yobwezeretsanso mtundu, yoyenera pazochitika zomwe zimafunikira kuzindikira mtundu;

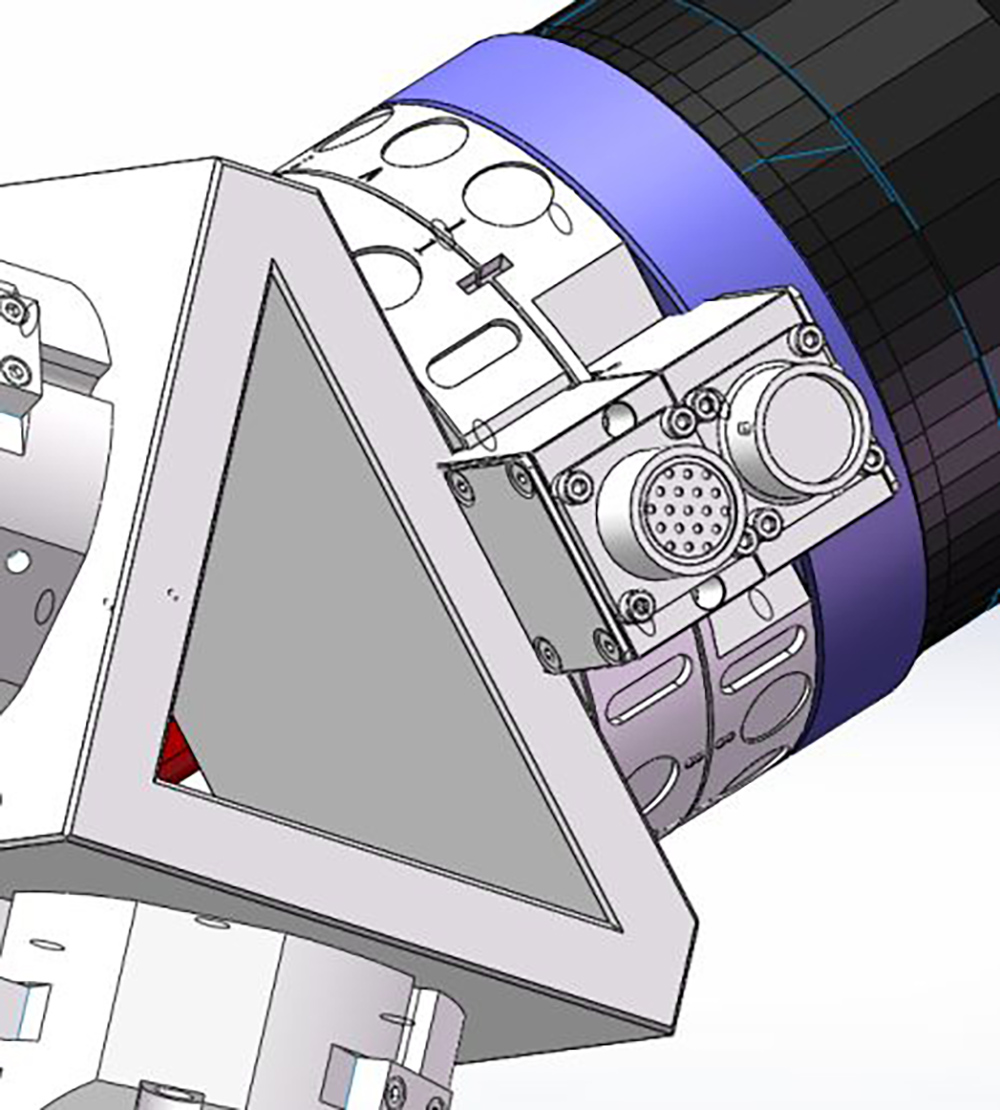

Kuyambitsa Angular Automatic Recognition System

Chiyambi cha Ntchito

1. Roboti imalimbitsa zida zogwirira ntchito kuchokera pamabasiketi onyamula ndikuzitumiza kumalo oyikirapo;

2. Turntable imazungulira pansi pa galimoto ya servo;

3. Makina owonera (makamera opanga mafakitale) amagwira ntchito kuti azindikire malo aang'ono, ndipo turntable imayima kuti idziwe malo omwe amafunikira;

4. Loboti imatulutsa chogwirira ntchito ndikuyika chidutswa china kuti chizindikirike cha angular;

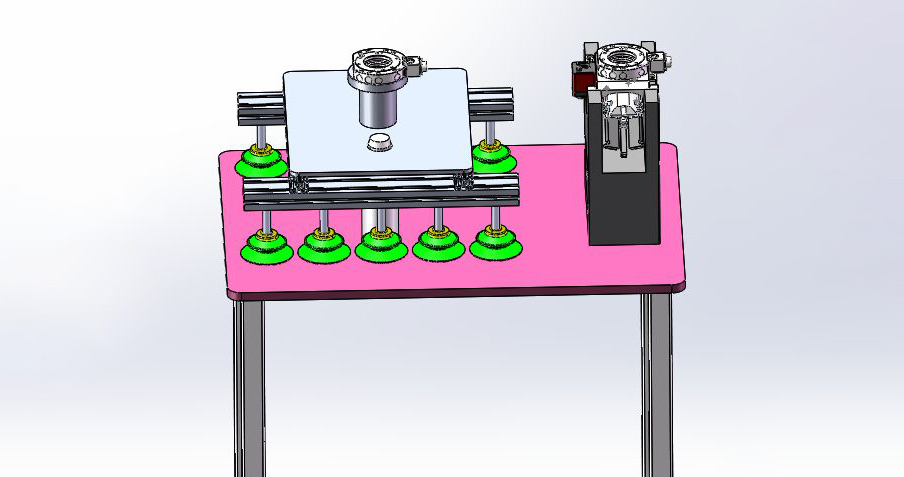

Chiyambi cha Workpiece Roll-over Table

Malo osinthira:

1. Roboti imatenga chogwirira ntchito ndikuchiyika pamalo oimikapo patebulo lopukutira (kumanzere pachithunzichi);

2. The loboti limagwira workpiece kuchokera pamwamba kuzindikira rollover wa workpiece;

Kuyika tebulo la robot

Chiyambi cha Ntchito

1. Pambuyo pa gawo lililonse lazigawo zodzaza, mbale yogawaniza idzayikidwa mudengu losungirako losakhalitsa la mbale zogawa;

2. Lobotiyo imatha kusinthidwa mwachangu ndi zibayo zoyamwa kapu ndi chosinthira chosinthira ndikuchotsa mbale zogawa;

3. Mabale ogawa akaikidwa bwino, chotsani kapu yoyamwitsa ndikusintha ndi chibayo cha pneumatic kuti mupitilize kulongedza ndi kutseka;

Dengu la kusungirako kwakanthawi kwa mbale zogawa

Chiyambi cha Ntchito

1. Dengu losakhalitsa la mbale zogawanitsa limapangidwa ndikukonzedwa pamene mbale zogawa kuti zilowetsedwe zimachotsedwa kaye ndipo mbale zogawanitsa zomwe zimasonkhanitsidwa zimagwiritsidwa ntchito pambuyo pake;

2. Magawo otsegulira amayikidwa pamanja ndipo sakulumikizana bwino. Pambuyo poyika mbale yogawanitsa mudengu losungirako kwakanthawi, loboti imatha kutulutsa ndikuyiyika bwino;

Tabu lachitsanzo lamanja

Kufotokozera:

1. Khazikitsani mafupipafupi a masampu amanja amanja pamagawo osiyanasiyana opangira, omwe amatha kuyang'anira bwino ntchito yoyezera pa intaneti;

2. Malangizo Ogwiritsira Ntchito: Wogwiritsa ntchitoyo adzayika chogwirira ntchito pamalo okhazikitsidwa patebulo lachitsanzo malinga ndi ma frequency omwe akhazikitsidwa pamanja, ndikuyambitsa ndi kuwala kofiira. Woyang'anira adzasindikiza batani kuti anyamule chogwiritsira ntchito kumalo otetezeka kunja kwa chitetezo, atenge chogwiritsira ntchito kuti ayese ndikuchisunga padera pambuyo poyeza;

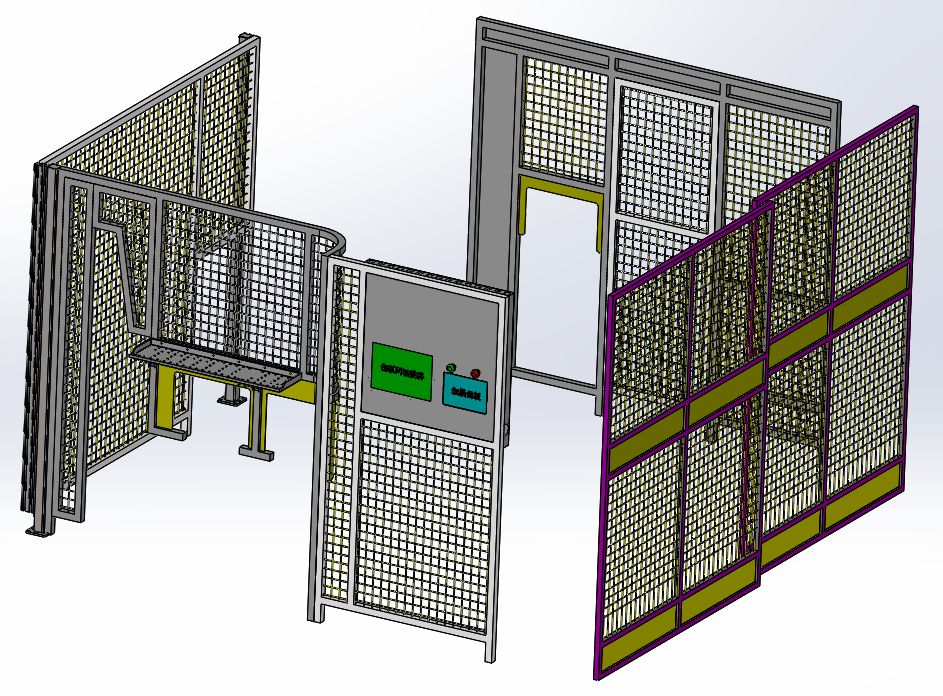

Zigawo zoteteza

Zimapangidwa ndi mbiri ya aluminiyamu yopepuka (40 × 40) + mauna (50 × 50), ndipo chotchinga chokhudza ndi batani loyimitsa mwadzidzidzi zitha kuphatikizidwa pazigawo zoteteza, kuphatikiza chitetezo ndi kukongola.

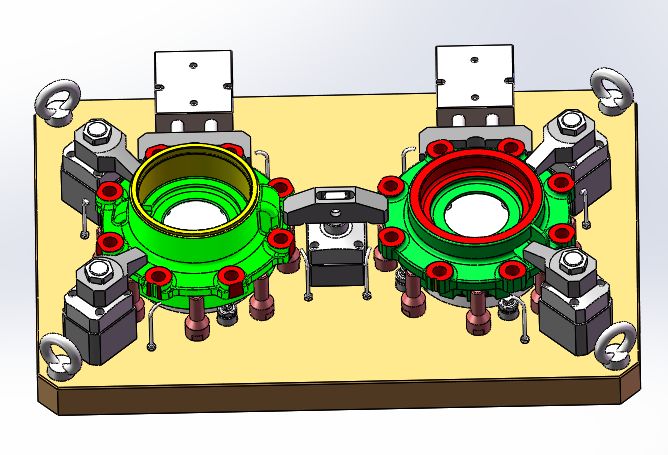

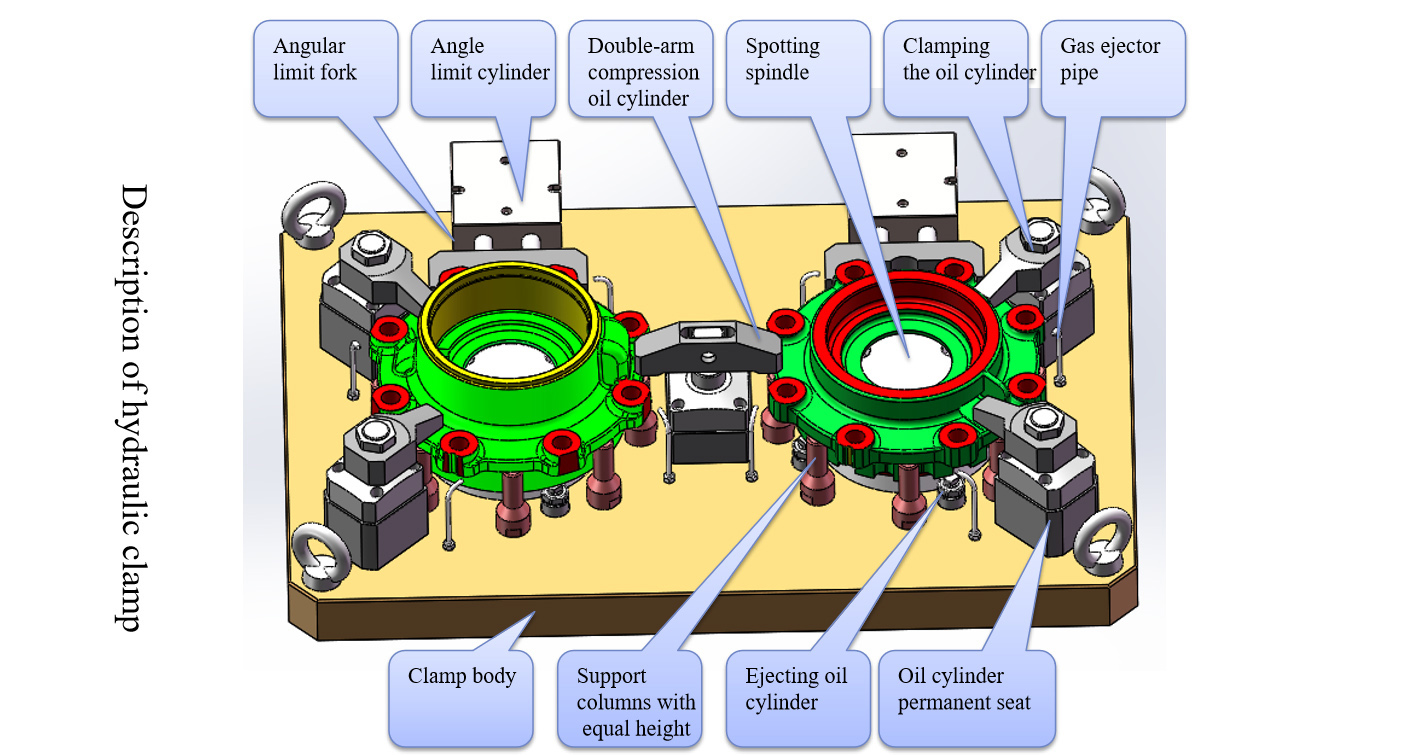

Kuyambitsa kwa OP20 Hydraulic Fixture

Malangizo Okonzekera:

1. Tengani chibowo chamkati cha φ165 ngati dzenje loyambira, tengani D datum ngati ndege yoyambira, ndikutenga arc yakunja ya bwana wa mabowo awiri okwera ngati malire;

2. Kuwongolera kumasula ndi kukanikiza kachitidwe ka mbale yosindikizira ndi lamulo la chida cha makina M kuti mutsirize kukonzanso kwa ndege yapamwamba ya bowo lokwera, 8-φ17 dzenje lokwera ndi malekezero onse a dzenje;

3. Chipangizocho chili ndi ntchito zoyika, kuwongolera, kuwongolera mpweya, kumasula zokha, kutulutsa basi, kuwulutsa kwa chip ndi kuyeretsa zokha poyika ndege ya datum;

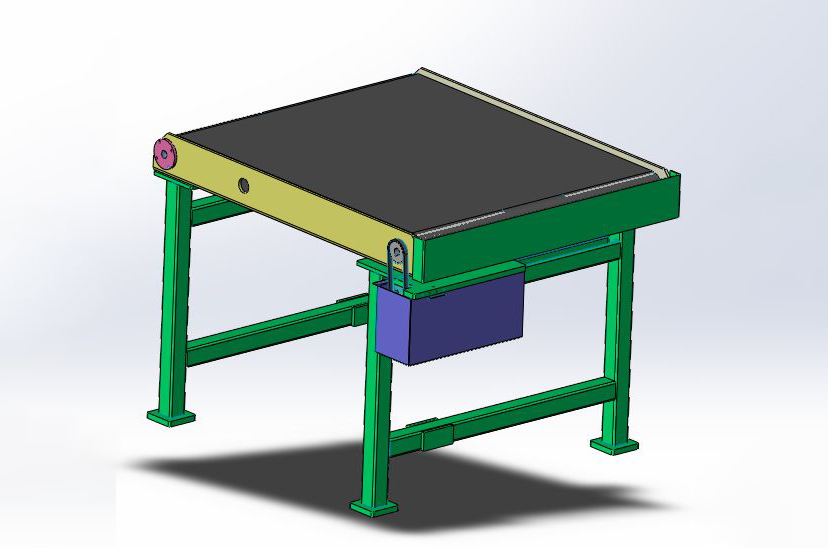

Zida Zofunikira Pakupanga Line

1. Chingwe chopangira zida zopangira zida chimakhala ndi ntchito zongobowoleza ndi kumasula, ndipo zimazindikira kuwongolera ndi kumasula ntchito motsogozedwa ndi ma siginecha a makina owongolera kuti agwirizane ndi kutsitsa ndi kutulutsa;

2. Malo a skylight kapena gawo lachitseko chodziwikiratu chidzasungidwa kwa mbale yachitsulo ya zipangizo zopangira mzere, kuti zigwirizane ndi chizindikiro chowongolera magetsi ndi kulankhulana kwa manipulator a kampani yathu;

3. Zida zopangira mzere zimakhala ndi kuyankhulana ndi woyendetsa pogwiritsa ntchito njira yolumikizira katundu wolemetsa (kapena pulagi ya ndege);

4. Zida zopangira mzere zili ndi malo amkati (osokoneza) ochulukirapo kuposa njira yotetezeka ya manipulator nsagwada;

5. Zida zopangira mzere ziyenera kuwonetsetsa kuti palibe tchipisi tachitsulo chotsalira pa malo otchinga. Ngati ndi kotheka, kuwomba kwa mpweya kudzawonjezedwa pakuyeretsa (chuck idzazungulira poyeretsa);

6. Zida zopangira mzere zimakhala ndi kusweka kwa chip kwabwino. Ngati ndi kotheka, chipangizo chothandizira chamakampani athu chidzawonjezedwa;

7. Pamene zida zopangira mzere zimafuna kuyimitsidwa kolondola kwa chopondera cha makina, onjezerani ntchitoyi ndikupereka zizindikiro zofananira zamagetsi;

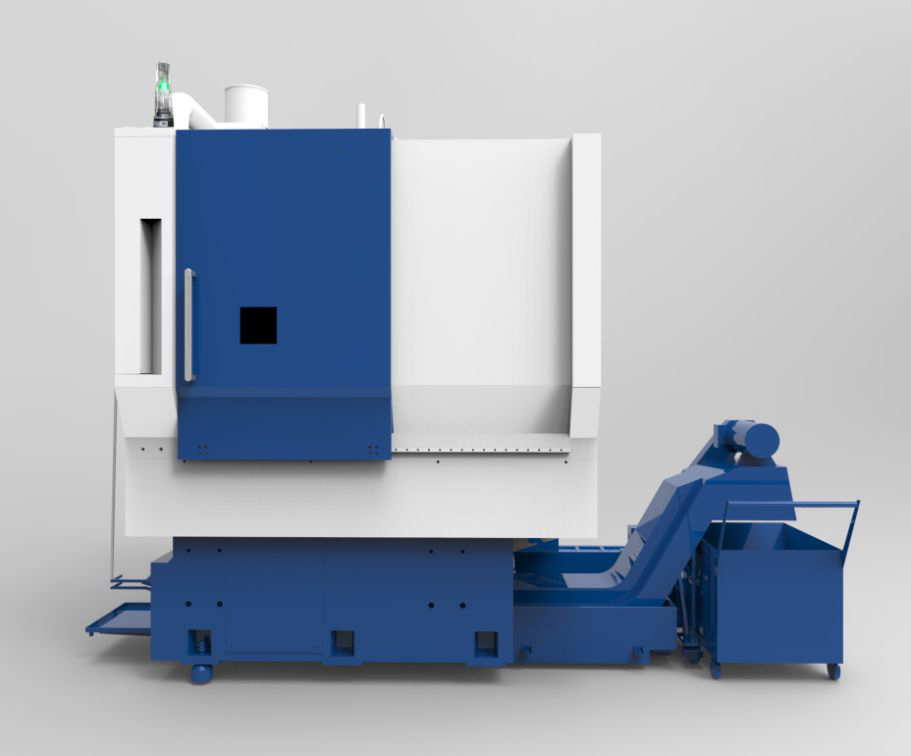

Kuyamba kwa Vertical Lathe VTC-W9035

VTC-W9035 NC ofukula lathe ndi oyenera makina makina ozungulira monga akusowekapo zida, flanges ndi zipolopolo zooneka mwapadera, makamaka oyenera yolondola, ntchito yopulumutsa ndi bwino kutembenukira mbali monga ma disks, hubs, ananyema zimbale, matupi mpope, ma valve matupi ndi zipolopolo. Chida cha makina chimakhala ndi ubwino wokhazikika bwino, kulondola kwakukulu, kuchotsera kwakukulu kwachitsulo pa nthawi ya unit, kusungidwa bwino kolondola, kudalirika kwakukulu, kukonza kosavuta, etc. ndi ntchito zosiyanasiyana. Kupanga mzere, kuchita bwino kwambiri komanso mtengo wotsika.

| Mtundu wa chitsanzo | Chithunzi cha VTC-W9035 |

| Kutembenuza kwakukulu kwa thupi la bedi | Φ900 mm |

| Kutembenuza kwakukulu kwa mbale yotsetsereka | Φ590 mm |

| Maximum kutembenuza awiri a workpiece | Φ850 mm |

| Kutalika kotembenuka kwa workpiece | 700 mm |

| Kuthamanga kwa spindle | 20-900 r/mphindi |

| Dongosolo | FANUC 0i - TF |

| Kupambana kwakukulu kwa X/Z axis | 600/800 mm |

| Kuthamanga kwachangu kwa X/Z axis | 20/20 m/mphindi |

| Kutalika, m'lifupi ndi kutalika kwa chida cha makina | 3550*2200*3950 mm |

| Ntchito | Chigawo | Parameter | |

| Mtundu wokonza | Ulendo wa X axis | mm | 1100 |

| Ulendo wa X axis | mm | 610 | |

| Ulendo wa X axis | mm | 610 | |

| Mtunda kuchokera ku mphuno ya spindle kupita ku benchi yogwirira ntchito | mm | 150-760 | |

| Benchi yogwirira ntchito | Kukula kwa workbench | mm | 1200 × 600 |

| Maximum katundu wa workbench | kg | 1000 | |

| T-groove (kukula × kuchuluka × malo) | mm | 18 × 5 × 100 | |

| Kudyetsa | Kuthamanga kwachangu kwa X/Y/Z axis | m/mphindi | 36/36/24 |

| Spindle | Njira yoyendetsera | Mtundu wa lamba | |

| Spindle taper | Mtengo wa BT40 | ||

| Kuthamanga kwakukulu kwa ntchito | r/mphindi | 8000 | |

| Mphamvu (Zovoteledwa/Zapamwamba) | KW | 11/18.5 | |

| Torque (Yovotera/Yopambana) | N·m | 52.5/118 | |

| Kulondola | X/Y/Z kulondola kwa malo axis (lopu yotsekedwa theka) | mm | 0.008 (utali wonse) |

| X/Y/Z kubwereza kolondola kwa axis (theka lotsekedwa) | mm | 0.005 (utali wonse) | |

| Magazini ya Tool | Mtundu | Chimbale | |

| Chida magazini mphamvu | 24 | ||

| Kukula kwachida chachikulu(Chida chathunthu cham'mimba mwake / chopanda chilichonse chozungulira chida / kutalika) | mm | Φ78/Φ150/ 300 | |

| Zolemba malire chida kulemera | kg | 8 | |

| Zosiyanasiyana | Kuthamanga kwa mpweya | MPa | 0.65 |

| Mphamvu yamphamvu | KVA | 25 | |

| Chida chonse cha makina (kutalika × m'lifupi × kutalika) | mm | 2900×2800×3200 | |

| Kulemera kwa chida cha makina | kg | 7000 | |